Plate Heat Exchangers sorted by applications

Brazed Plate Heat Exchangers up to the specified application

This category includes cataloged plate heat exchangers that, due to some parameters, are a good solution for specific heating or cooling applications. On the left you will find subcategories that also contain tips on the correct selection of plate heat exchangers for a given application.

Between them we selected the right PHE models cooperating with most common devices, like boilers, fireplaces or heat pumps. Additionally electric furnace or some cooling applications.

Plate heat exchangers - various applications

Plate heat exchanger - a passive device - that operates by transferring heat energy between two working fluids (such as water, glycol, oil etc) without direct contact, without mixing - which is very important. Plate heat exchangers are essential components in various installations, including gas boilers, heat pumps (especially monoblock) or water-jacketed fireplaces (in fact the heat source list could be much longer). The PHE are also used in hobbyist applications like home brewing. Before purchasing a heat exchanger, it is important to consider its technical specifications and intended application - to size a model that perfectly suits individual needs or our heating / cooling system.

In Nordic Tec Heat Exchangers - our online store, we offer a wide range of plate heat exchangers classified basing on their applications. Our product range includes low-power devices suitable for small residential houses or even vacation homes as heating system components, as well as high power heat exchangers - that are ideal for more complex heating systems in bigger building. We invite you to explore our selection of heat exchangers.

Online Shop with plate heat exchangers for your needs - Nordic Tec Europe

A heat exchanger is a device that generally has a beneficial impact on the efficiency of a heating system, by balancing the pressures and temperatures throughout the heating circuits (in this aspect a PHE is a bit similar to a hydraulic separator for a central heating - but the working principle is different and both devices are used a bit different way). PHE also serves as a separator between systems operating in an open loop (e.g., solid fuel boiler system) and systems operating in a closed loop (e.g., gas boiler system, radiator system, underfloor heating system). The applications of plate heat exchangers are very broad, which is why we have categorized our offered models based on their applications - to make the sizing and dimensioning easier.

The online store Nordictec-store.com offers a wide range of plate heat exchangers - known for their high efficiency and durability. Proper sizing of the device is a fundamental requirement. We provide heat exchangers for central heating, heat pumps, and water jacket fireplaces, among others. NORDIC TEC - as a manufacturer with years of experience in the industry, you can trust the high quality of our products. Our store features plate heat exchangers in various sizes and with different specifications, and if you need assistance, our support team is ready to help.

Heat transfer is a crucial process in many installations, so it is worth investing in high-quality heat exchangers that not only ensure efficient operation but also guarantee safety. We offer competitive prices, professional advice, and fast and secure shipping. We invite you to explore our product range and take advantage of our services.

Types of plate heat exchangers based on their purpose

Heat exchangers are used in various heating systems, such as central heating systems with gas heating or solid fuel boilers, systems with electric boilers, systems powered by heat pumps or with water jacket fireplace as an additional heat source... They are also increasingly being installed in systems based on renewable energy sources (solar, heat pumps) and hybrid systems. In the offer of the Nordictec-store.com - you will find the following types of plate heat exchangers:

- heat exchangers for gas boilers;

- heat exchangers for central heating boilers - for different fuel

- heat exchangers for heat pumps;

- heat exchangers for fireplaces;

- heat exchangers for electric and electrode boilers;

- heat exchangers for home brewing (wort coolers).

Characteristics of plate heat exchangers

Plate heat exchangers are devices composed of numerous thin plates, typically made of stainless steel, interconnected through twisting or soldering. In general, the larger the number of plates and their surface area, the more efficiently the heat exchanger operates. To further enhance the performance, specially profiled plates are used, increasing the heat transfer surface area while maintaining the compact dimensions of the device.

The construction of the plate heat exchangers offered by <Nordic Tec Europe> has been designed to ensure maximum efficiency in heat exchange between the media. They are resistant to temperature and pressure variations, ensuring safety and longevity. Each of our plate heat exchangers is made from high-quality materials, guaranteeing not only high performance but also durability and reliability. We invite you to browse and explore our range of plate heat exchangers - and take advantage of the professional services provided by our store. Our products deliver the highest quality, durability, and effectiveness, allowing for the optimal utilization of heat transfer potential in various processes, both heating and cooling.

Heat exchangers in central heating systems - types

Are you looking for a device to exchange heat between different circuits in your entire heating system? Before making a purchase, you should know - that there are generally two main types of plate heat exchangers. They operate on a similar principle but differ in their construction, specifically the method of plate connection is different. If you are not a represenatative of a industrial branch, but you are looking for a PHE for your house heating system, to connect a heat pumps, condesing boiler, make a passive cooling in your house - or similar purposes - you'll be interested only in BPHE, because the other type is used almost only in industrial applications - or in very large facilities.

- Brazed plate heat exchangers (BPHE) for central heating systems - the plates in the heat exchanger are connected through brazing. The characteristic feature of these types of {PHE is their small size and high efficiency. They can be used in various installations.

- Gasketed heat exchangers for central heating systems - the plates in the heat exchanger are connected using a frame and gaskets. Due to their larger size, their application is less common compared to brazed models.

Key parameters of Plate Heat Exchangers

The key parameters that affect the quality and utility of heat exchangers include:

-

Type: This parameter indicates the two mediums between which the energy exchange occurs in the heat exchanger. There are models available on the market that facilitate heat exchange between liquid or gas media. Check this, especially if you're looking for a PHE for freon or other high-pressure medium

-

Capacity: This parameter has a significant impact on the efficiency and application of the plate heat exchanger

-

Maximum operating temperature: Typically up to 230°C. Here, no reason to worry, as we see it's not possible to achieve this in home conditions

-

Maximum working pressure: Typically up to 10 or up to 30 bars. Home instalaltions (liquid to liquid) are in most cases no more than 3-4 bar. Be cautious when you are looking for a high pressure media, like freon, cooling factors R32 and similar.

-

Material: The material from which the heat exchanger is made determines its durability, heat conductivity, and resistance to corrosion. The best is S316L, or a bit worse but still acceptable S304

-

Heat transfer surface area: This refers to the number and surface area of the plates in the heat exchanger. A larger surface area leads to more efficient heat transfer.

What to consider when choosing a heat exchanger?

The primary criterion to consider when purchasing a plate heat exchanger is the heat transfer surface area. In the case of heating systems, this parameter should be dependent on the nominal power of the boiler with which it will operate. Additionally - factors such as the supply temperature from the heat source, especially in reference to heat pumps - can affect the heat exchanger's efficiency. It is important to keep this in mind in order to select a PHE that precisely meets our expectations and operates reliably for a long time. The sizing of a heat exchanger should not be made by individuals without knowledge in this field. It should be noted that not every plumber possesses such expertise, as heat exchangers are not devices encountered in every heating system. In case of doubts, it is advisable to seek technical assistance from the store.

Heat Exchangers for glycol circuits - for heat pumps or other heat sources

It is also worth remembering that when using glycol, its thermal properties should be taken into account. It is commonly used as an antifreeze fluid - but few people consider why it has antifreeze properties. The reason is that it does not release heat as easily as water. When using glycol, according to our estimations, heat transfer is hindered by about 8-15%. However, this can be completely offset by selecting an appropriate heat exchanger, just a bit oversized proportionally to this loss. Considering the safety benefits that glycol provides, for example, to our heat pumps, there is no need and no point to abandon its use; rather, it is important to choose the right heat exchanger for glycol.

Installation and operation of plate heat exchangers

The installation of plate heat exchangers require proper knowledge and skills - even if the operation requires almost no service. The first step is to select a suitable heat exchanger that meets the technical requirements and operating parameters. Then, the installation site needs to be prepared carefully, and the heat exchanger should be positioned correctly (in a vertical position, obligatory factor). Proper installation is essential, including connecting the pipes to the heat exchanger, installing filters at the inlets, and conducting efficiency tests. Here are a few tips to keep in mind during the installation of a plate heat exchanger:

- Plate heat exchangers should be installed in a vertical position.

- The air vent valve should be located at the highest possible point in the installation.

- Install a safety valve - between the heat exchanger and the shut-off valve.

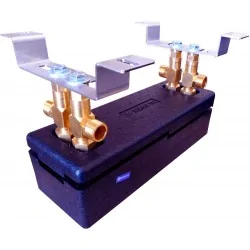

- Use mounting brackets for brazed heat exchangers, especially if they are heavy PHE

- Exercise caution during installation to ensure proper connection of the primary and secondary circuits

After completing the installation process, transitioning to operation requires a thorough understanding of the technical parameters and adherence to safety principles. Regular maintenance and periodic inspections help maintain the HE proper condition and ensure long-term usage of plate heat exchangers.