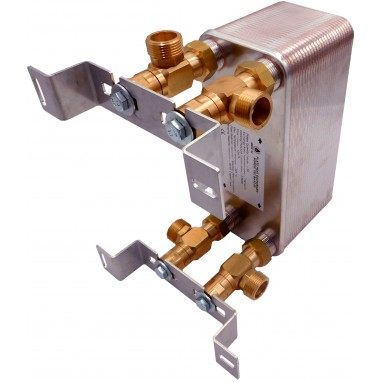

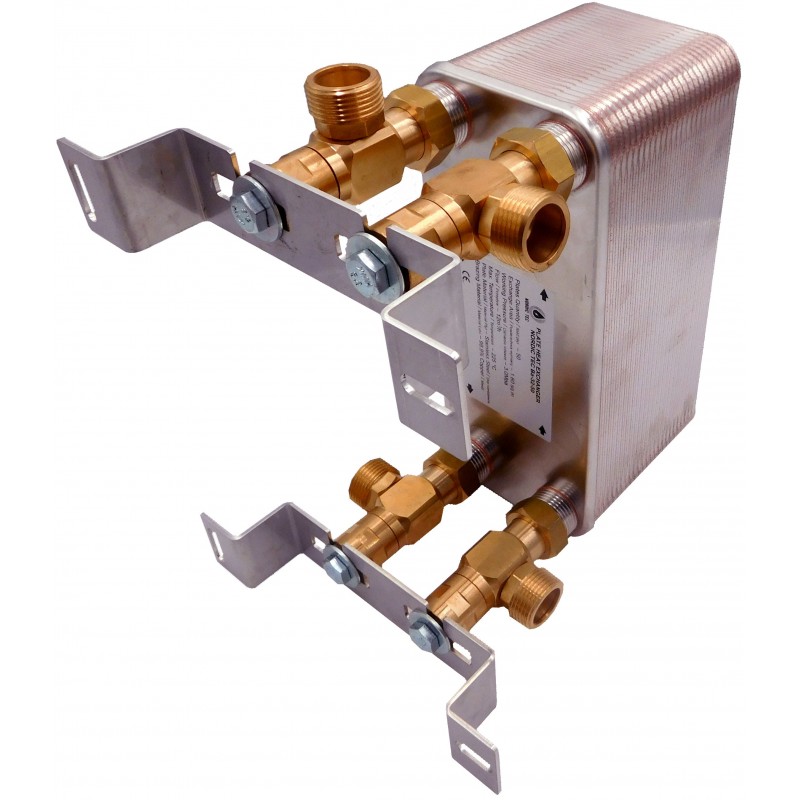

Plate Heat Exchanger NORDIC Ba-16-40 1" 150kW

40-Plate Brazed Heat Exchanger for central heating or DHW systems by NORDIC TEC Ba-16-40

50 kW brazed plate heat exchanger – traditional model with four 1-inch outlets.

A model of heat exchanger commonly used for separating various types of boilers – gas, solid fuel, and fireplaces – typically within the range of 20–25 kW.

- Plate Q'ty: 40 pcs.

- Connections: 1" BSP

- Heat Exchange Area: 0.640m²

☑️ Quick consultation of sizing a heat exchanger by our team

✅ Free shipment in the following countries:

ES, FR, IT, AT, DE, NL, BE, PL, DK, CZ, LT, LV, SI, EE

Reference: NT Ba-16-40

Condition New

Heat Exchanger 1" for central heating Nordic Tec Ba-16-40 - 4x 1", 40 plates

Technical details - Heat Exchanger 1" for central heating Ba-16-40

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 1", BSP

- Working Pressure - <20 bar

- Test Pressure - 40 bar

- Max. temperature +230°C

- Flowrate - 8 m³/h

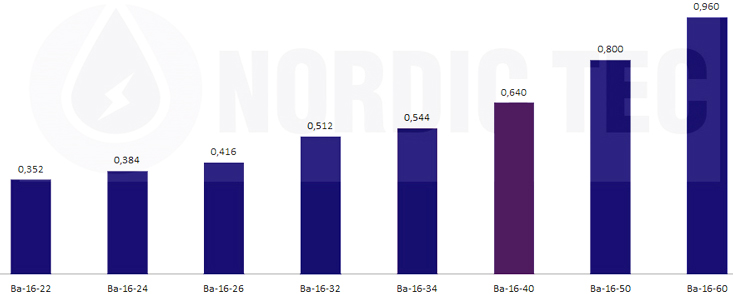

Heat Exchange Surface - Plate Heat Exchanger NORDIC Ba-16-40 - 0.640 m²

The Nordic Tec Ba-16-40 heat exchanger has a heat exchange surface area of 0.64 m². It is ideal for supporting boilers with a power output of up to 20–25 kW, as well as fireplaces with similar power.

If you are looking for a similar heat exchanger but with a higher capacity, take a look at models with a greater number of plates, such as the Ba-16-50 (50 plates) or the Ba-16-70 (70 plates).

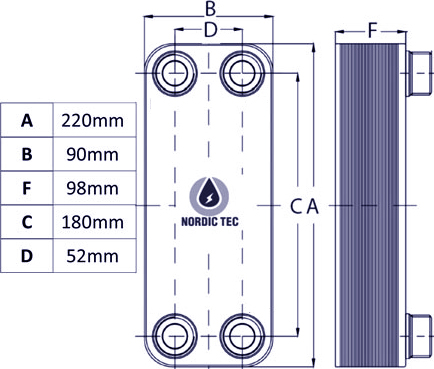

Dimensions - Plate Heat Exchanger Ba-16-40

Small FAQ - frequent questions from the Buyers:

What is the weight of the Ba-16-40 plate heat exchanger?

The Ba-16-40 plate heat exchanger weighs approximately 2.8 kg, but if we plan installing it in our boiler room we should remember that it will be filled up with water. This means it can achieve the weight of cca. 4 kg.

What is the maximum flow rate of the Ba-16-40 plate heat exchanger?

The Ba-16-40 PHE can handle a maximum flow rate of 8 m³/h, but in fact when designing in order to not overcharge our circulation pumps - we should work with a flowrate of < 75% of the maximal capacity. Over this value the pressure ressistance grows up significantly. If we need something with a bigger flow capacities, but with relatively similar heat exchange area - we recommend the PHE Ba-32-20.

How often should the Ba-16-40 plate heat exchanger be serviced?

Recommendations about servicing a plate heat exchanger are in fact quite similar for every brand or producer - and they limit to more or less regular cleaning, which can make the life of the device much longer. It is recommended to clean our PHE at least once a year to ensure optimal longevity. This is the only maintenance of the unit, as well as checking for possible signs of wear. In fact not cleaned PHE units rarely get dommaged, but they work potentially less years than they could if there were services. We insist to not skip cleaning especially in older systems.

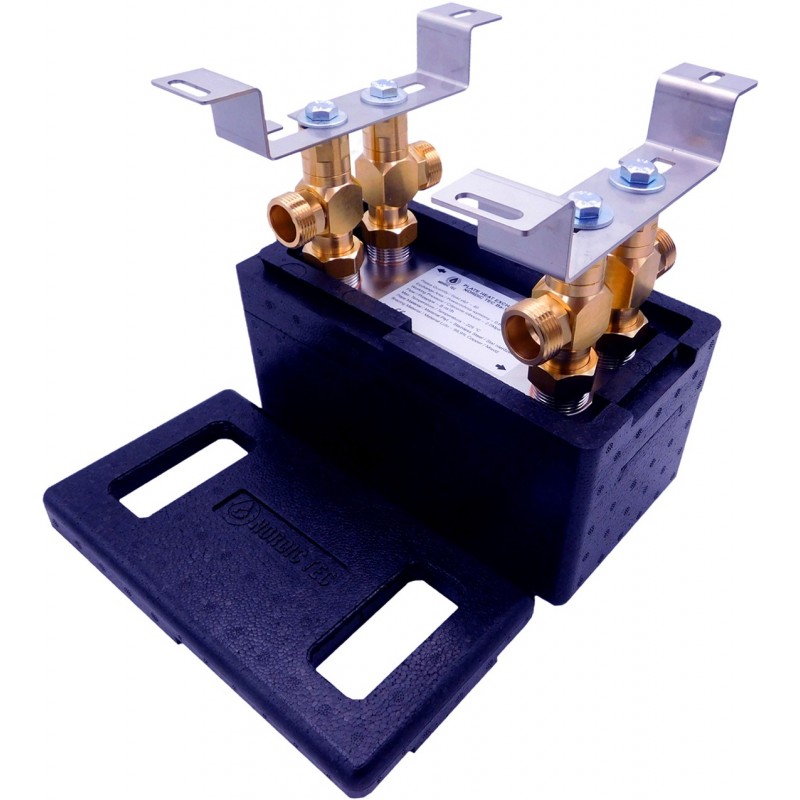

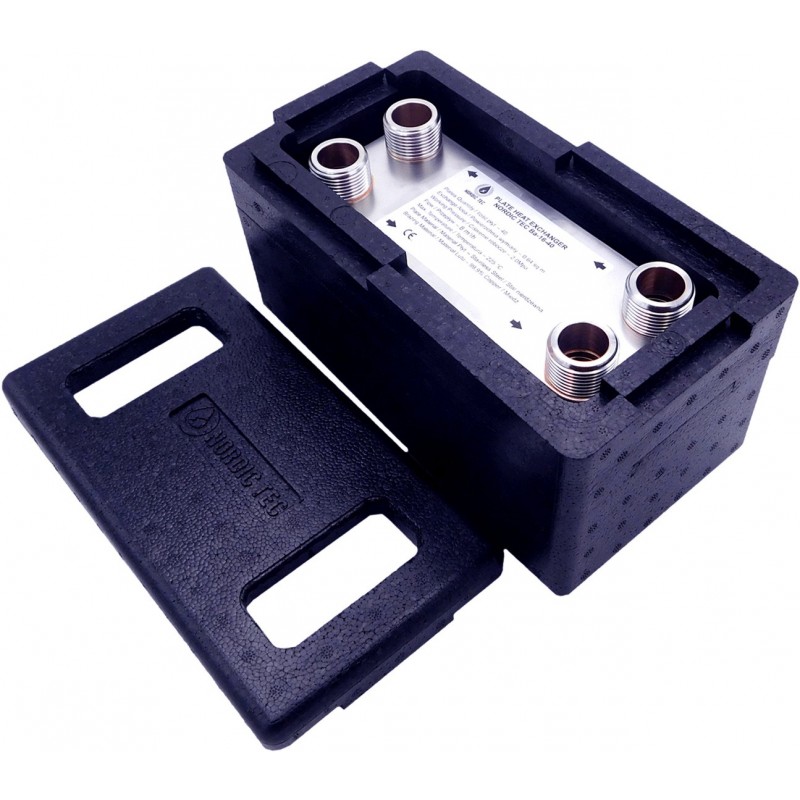

Is thermal insulation necessary for a heat exchanger? How will a plate heat exchanger work without insulation?

Insulation IZ-Ba-16-40 is not essential – however, we must be aware that the heat exchanger releases part of the heat supplied to it by the boiler, heat pump, or fireplace, also to the outside. In this way, it slightly heats the room where it is located – which is usually unnecessary, for example, a boiler room. How significant these losses are depends mainly on the external surface area of the heat exchanger, as well as on the ambient temperature and the device’s supply temperature. Typically, such losses are estimated to range from a few to even several percent.

If we want to create an efficient and cost-effective heating system, it is recommended to insulate every major component of the central heating installation. Otherwise, we are paying for heat that warms up the boiler room or basement. Considering how large these losses can be, the insulation pays for itself fairly quickly. Therefore, in heating systems, we strongly recommend its use, while in cooling systems – it is, of course, unnecessary.

NT Ba-16-40

157 Items

New

No reviews

You might also like