Heat Exchangers for heat pumps

How to choose a Nordic Tec plate heat exchanger to connect the heat pump to the heating system

Heat pumps as a heating device are quite a demanding solution from the point of view of heat exchange, which translates into the objective need to select a heat exchanger with a larger area than, for example, for classic boilers of similar power. The reason is both the fact that they usually operate at much lower deltas, as well as the desire to ensure that the heat pump works with the lowest possible power consumption, as a rule.

Below we present a series of types of heat exchangers that are most often sold for heat pumps. Of course, it is about connecting the HP to the installation, in the water-water or water-glycol system, these are not freon exchangers or the units for the so-called R factors.

In the case of heat pumps, the selection depends not only on the nominal power of the HP, but also on the temperatures at which the central heating system is to operate. This is not about the maximum performance of the pump, but rather about the operating temperature that we expect from the pump so that it is able to provide thermal comfort at home. The lower it is - the larger the heat exchanger will be needed, but it is worth keeping it as low as possible, due to the expected operating costs.

The plate heat exchanger for a heat pump should be sized depending on the expected operating temperature of the pump

The first case is a classic arrangement - in which radiators play the main role, and floor heating is possibly an addition. In such a facility, the operating temperature of the pump must be min. approx. 50 °C for the radiators to work optimally. For such systems, approx. 1.50 m² of the heating exchange area should cover each 10 kW of the heat pump (working on 50°C).

The second case is facilities heated in 100% with underfloor heating, where the operating temperature of the pump will be required at the level of about 30 - 35 °C only. In such cases, the heat pump works very economically, but a relatively large heat exchanger system is needed for efficient operation - the sizing converter here is approx. 3.0 m² of heat transfer area for every 10 kW of heat pump (operation at 35°C).

Intermediate options, i.e. supply temperatures of 40 or 45 °C, should be sized proportionally.

The presented sizing PHE by converting a transfer are to the HP nominal power can be applied both for monobloc and split types.

These are proven conversion factors that provide a healthy supply allowing for operation for many seasons (taking into account the aging of heat exchangers over the years), the use of glycol and the possibility of efficient operation with minimal temperature differences (i.e. minimal energy consumption as well as minimal wear of the heat pump itself). You can decide to reduce them on your own if there are objective reasons for doing so, such as water instead of glycol. However, while expecting the above benefits to be achieved, the above conversion factors should be taken into account. In case of doubt, you can also confirm the selection PHE by contacting the service of the manufacturer or distributor of HP.

If you have difficulties with the selection of a PHE for a heat pump - write to us

If you have difficulties with the selection of a PHE for a heat pump - write to us

Plate heat exchangers for heat pumps | Nordic Tec Europe

Heat pumps are becoming increasingly popular practically in whole Europe. They provide real comfort, are environmentally friendly, and energy-efficient, allowing the utilization of energy from renewable sources (such as - photovoltaic panels) for heating purposes. Heat pumps work in the opposite way - to the natural flow of heat in nature, meaning they transport energy from a medium at a lower temperature to a medium at a higher temperature. Depending on the HP type, they can extract heat energy from the air, water, or ground.

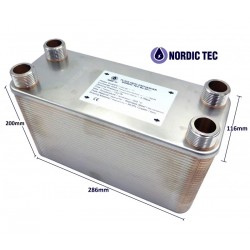

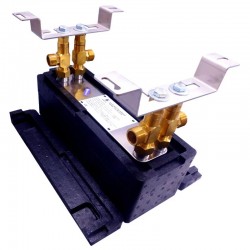

Plate heat exchangers in this category are used to connect heat pump systems with central heating systems. The plate heat exchangers available at Nordictec-store.com are characterized by excellent flow parameters, energy efficiency - and reliability. They can be used in both small and large heat pumps, assuming proper selection of PHE. The application of these plate heat exchangers allows for system optimization with minimal heat loss - which can be reduced to below 1°C in a properly functioning system. Additionally there is an opportnity of increasing the effectivity of the whole heat transfer using a thermal insulation for heat exchanger.

By investing in plate heat exchangers for heat pumps, you can increase the efficiency of your whole heating system - while retaining the option to protect the heat pump system from frost - with glycol. It is expected by some heat pump manufacturers - and recommended especially in some European areas.

The store where you can purchase a heat pump plate heat exchanger | Nordictec-store.com

<Nordic Tec Europe> is an online store that offers a wide selection of plate heat exchangers for heat pumps - and provides fast deliveries to practically every European country. We are able to match the appropriate PHE model to almost any device. Our range includes a large variety of options, allowing Customers to choose the heat exchanger that best suits their individual requirements or specific heat pump model. All our products are made of high-quality material - S316 stainless steel, ensuring their durability for years. Our team is always available to provide technical assistance and help in selecting plate heat exchangers perfectly suited to your installation.

Plate heat exchanger for a heat pump - working principle

The heat exchanger of a heat pump is responsible for the heat exchange - between the medium inside the HP unit and the medium in the connected circuit. Since plate heat exchangers for heat pumps are constructed with a series of interconnected thin steel plates, thermal energy is effectively transferred between the two circuits without mixing them. The thermal energy generated by the heat pump is efficiently transported to heat emitters (radiators, underfloor heating) or utilized for domestic hot water (DHW) heating. Considering that the working fluids do not mix in the heat exchanger and only the transfer of thermal energy takes place, heat exchangers for heat pumps can be used for connecting heat pumps to heating systems or DHW in a glycol/water system without the risk of mixing the individual mediums. This cathegory and the description doesn't refer to internal HE of a heat pump and for freon units, but for the heat exchanger which are invented to divide the heat pump circuit from the installation (which is in some cases profitable, for different reasons).

In this way, the plate heat exchanger allows for connecting the heat pump to the system - while keeping the option of using glycol - without the need to fill the entire installation with glycol (which would be expensive and not recommended, because of the glycol's thermal inertia). If the decision is made to operate the heat pump with water without the addition of glycol, the heat exchanger acts as a protection for the pump system from the installation system (which may generate impurities and boiler scale, sometimes due to operating in an open system). In such a situation, the heat exchanger also plays a role similar to a hydraulic separator to some extent - because by creating two independent circuits instead of one extensive system, it helps balance pressures and temperatures throughout the system. Often, when opting for a heat exchanger in a pump system, the additional hydraulic separator can be dispensed with.

Key parameters of a plate heat exchanger for a heat pump

When selecting a plate heat exchanger for a heat pump, it is worth considering the following aspects

-

Heat exchange surface area: The surface area of the plates in the heat exchanger should be appropriate for the nominal power of the heat pump and take into account the operating temperature of the entire system

-

Type of heat exchanger: Plate heat exchangers can be brazed or gasketed. Brazed plate heat exchangers are smaller and more versatile - while gasketed ones allow for power adjustment by adding or removing plates. Nordic Tec catalog offers brazed PHE.

-

Heat exchanger capacity: The capacity of the heat exchanger should be matched to the requirements of the entire system. Nordictec-store.com offers heat exchangers ranging from 10 kW to 1000 kW.

-

Number of plates: In most cases a larger number of plates generally results in higher efficiency of the heat exchanger for the heat pump, but this is not always the case, superior value is a heat transfer area

-

Optimal operating pressure: Heat exchangers for liquid/liquid systems typically operate at pressures rarely exceeding a few bars, making most heat exchangers on the market compatible in this regard

-

Permissible operating temperature range: Plate heat exchangers are usually designed to operate reliably in temperatures ranging from -200°C to 220-230°C, making them suitable for heat pump applications, so we'll have definitely no problem while sizing this aspect

-

Working medium compatibility: Before purchasing, it is important to ensure that the heat exchanger is compatible with the working media used, such as water or air. Especially it is important to remember that not every PHE is allowed to be used with freon

-

Material of construction: The material of the heat exchanger should efficiently conduct heat while providing mechanical strength. The recommended choice is stainless steel S316, which is more resistant to limescaling - compared to the more common S304 stainless steel.

-

Application suitability: The product specifications provide information from the manufacturer regarding the intended use of the heat exchangers. It is advisable to choose a model explicitly specified by the manufacturer for use with heat pumps.

-

Dimensions : BPHE - brazed models need less space than gasketed exchangers. Therefore, it is important to check the dimensions to ensure sufficient space for installing the heat exchanger in a boilerroom

-

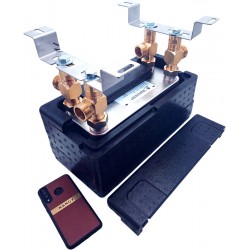

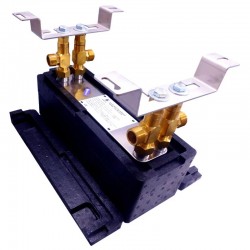

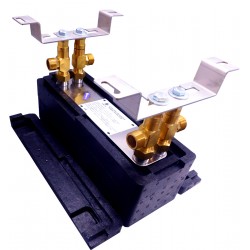

Possibility of adding insulation box: Consider the option of adding insulation jacket to the heat exchanger to optimize the system and minimize heat loss through the exchanger, which can range from a few percent of the thermal energy passing through it.

Plate heat exchanger for a heat pump - advantages

A plate heat exchanger for a heat pump is a convenient solution for anyone seeking comfortable heating in residential buildings. This type of heat exchanger is characterized by high efficiency and durability, with a lifespan of up to 10-15 years. Its special design enables fast, effective - and efficient heat transfer. One significant advantage of a plate heat exchanger for a HP is its compact size and lightweight construction, making installation much easier. These factors contribute to the widespread and increasing popularity of plate heat exchangers in the HVAC industry, providing time and cost savings while delivering excellent end results. Moreover, these heat exchangers require minimal maintenance from the user's perspective.