Heat Exchangers for a fireplace

Plate Heat Exchangers for fireplaces and water jackets

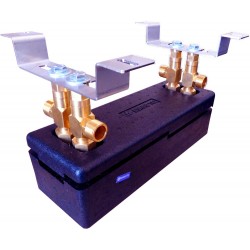

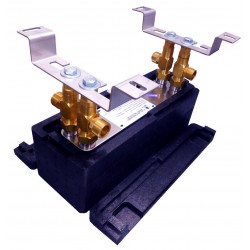

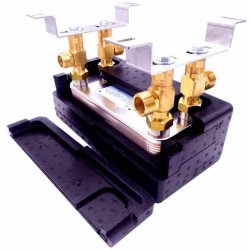

Below we present some PHE models - that we successfully sell for this application - that is, connecting an open-circuit fireplace (so called water jacket) with our sealed circuit installation (for example underfloor heating system). Of course - instead of a fireplace - the heating device can be as well traditional free-standing wood or coal burners - if they have a water jacket and have the opportunity of heating water.

The key is to size a plate heat exchanger with heat transfer area - of 0.30m2 (total plate surface) per 10kW of a fireplace or a water jacket.

As fireplaces are fairly inert heat sources - we suggest not reducing this conversion rate too much, even if the fireplace is oversized in relation to the heated building or apartment. Some lower conversion rate we could apply to the heat sources, which are easily controllable - as gas boilers, eco-pea boilers, pellet boilers.

When dimensionning a heat exchanger, you should take into account the connections' size, which should be discussed before purchasing - with the plumber responsible for fireplace installing.

If you still have doubts or questions about sizing a heat exchanger - feel free to write

If you still have doubts or questions about sizing a heat exchanger - feel free to write

Heat exchangers for fireplaces | Nordic Tec Europe

For many people, a fireplace is an absolute must-have in the living room - without which they can not imagine relaxing during long winter evenings. Installed in the central point of the room, it serves as a decoration - while helping to create a peaceful, family atmosphere. But - a fireplace installation serves not only to create the right ambiance in the room but also serves as a practical element that generates heat, which can be used for practical purposes such as central heating or producing hot water - helping DHW systems. A fireplace insert can not only warm up the room it is located in but also, with the use of a suitable fireplace heat exchanger, it can provide additional benefits.

Rising costs of gas, oil, pellet and other fuel types - the aesthetic appeal of fireplaces, advancements in fireplace insert technology, and even environmental considerations - all these aspects contribute to the increasing popularity of heating homes using fireplaces, at least as an additional heating device. The installation of a fireplace with a water jacket allows it to work in conjunction with the heating system while preserving all the benefits of a traditional fireplace. To connect it to the central heating or hot water system, it is worth considering an appropriate plate heat exchanger for a fireplace.

The store where you can buy a heat exchanger for a fireplace - is Nordictec-store.com

Water jacket fireplaces, similar to traditional solid fuel boilers, are devices that, for safety reasons shuold operate almost exclusively in an open vented system. This means - that one of the components of a fireplace installation is an open vessel in the highest point of the system - in which water comes into direct contact with atmospheric air. Considering that modern heating systems (such as radiator systems or underfloor heating) are built in closed systems (aslo called: sealed systems), it is necessary to use a fireplace heat exchanger that connects both circuits, without mixing them. Plate heat exchangers work best for this purpose, as they offer high efficiency despite their compact size.

In the online store Nordictec-store.com - you will find high-quality water jacket fireplace heat exchangers that stand out for their reliability. They have been crafted with the utmost care, ensuring they meet the requirements of customers who expect high quality and performance. Water jacket fireplace heat exchangers are highly functional devices that can be enjoyed without any faults for many years. Our range includes heat exchangers of various sizes and capacities, allowing you to customize them to suit the individual needs of your fireplace. We offer competitive prices, the option to purchase accessories for the exchanger (such as thermal insulation, mounting brackets, or shut-off valves), and professional technical assistance in choosing the appropriate model.

Heat exchangers for water jacket fireplaces - operating principle

The operating principle of a water jacket fireplace - is somewhat similar to that of a traditional central heating boiler. The energy generated from fuel combustion is directed to the water jacket located above the fireplace, heated directly by the fire. The water jacket essentially serves as a type of heat exchanger where the heat from the fire and exhaust gases is transferred to the water in the pipes of the water jacket. The water jacket is designed to maximize the surface area of its pipes, increasing efficiency. It consists of numerous thin channels made of heat-conductive material, effectively extracting and accumulating thermal energy in the flowing water.

Subsequently, the water is directed to a second plate heat exchanger whose role is to separate the fireplace circuit from the central heating system (as the fireplace operates in an open system while the central heating system is closed). In the plate heat exchanger for the fireplace, the thermal energy is transferred from the higher-temperature medium (water in the fireplace circuit) to the lower-temperature medium (water or another heat transfer fluid in the central heating system), thereby heating the water in the central heating installation.

Considering that the fireplace heat exchanger consists of numerous thin plates made of thin steel sheets, the exchange of thermal energy occurs quickly and efficiently. The water in the fireplace circuit is cooled down and redirected to the water jacket, while the heat transfer medium in the central heating system is heated and then transported to heat emitters (such as radiators or underfloor heating).

Fireplace heat exchanger - why is it worth it?

A fireplace with a water jacket and installed fireplace plate heat exchanger is a heating device that combines two advantages - the pleasure of having an attractive and safe hearth of the heating system - in the center of the home and the opportunity to save on heating costs, transferring the water jacket heat to our underfloor heating. By combining the fireplace with a central heating system, the energy generated from burning wood can be utilized more efficiently, thereby reducing the amount of fuel consumed by the main heat source, such as a gas boiler or coal burner. With the use of control automation, a fireplace with a plate heat exchanger can effectively support the operation of various heating devices, reliably working in conjunction with them. Moreover, it can also be used for domestic hot water heating.

There are no obstacles to connecting any open vented system - with any closed system using a plate heat exchanger. In this way, a fireplace can also support heating in a building - that is heated by a heat pump or other types of electric heating, like electric boilers and so on.

A well-executed and designed fireplace installation serves as an excellent and reliable supplement that is completely independent of any other conditions or factors. Its functionality is unaffected by gas supply interruptions, gas prices, or coal unavailability. It is also not affected by electricity price hikes or power outages, unlike heat pumps or electric heating mats. Naturally - a water jacket fireplace also utilizes circulating pumps, but they are energy-efficient enough that a UPS ("uninterruptible power supply") is sufficient to maintain their operation during power breaks. We can not say this about heat pumps or electic stoves.

One of the advantages of installing a fireplace with a water jacket and plate heat exchanger is that the system can serve as a backup in case of a main boiler failure or fuel supply issues. Diversifying heating sources in the building allows for partial independence from unforeseen events. This is the lesson we should draw from the fuel crisis of 2022 and 2023.

Plate heat exchanger for a fireplace - key parameters

The most important factor - to consider when purchasing a plate heat exchanger for a fireplace with a water jacket is the total surface area of the exchange plates. Generally, the more plates the fireplace heat exchanger has, the more efficiently it operates, at least when comparing plates of similar size. However, it is worth noting that specially profiled plates are used in plate heat exchangers to increase the heat exchange surface area. This approach also has a positive impact on the dimensions of the device. By using corrugated plates, the heat exchange surface area is increased while the overall dimensions of the PHE remain unchanged. As a result - it becomes easier to install and takes up less space. Additionally, it is important to choose a fireplace heat exchanger that matches the power of the fireplace itself and, if applicable, the size of the house it is intended to heat.