Gas Heat Exchangers Ba-68-F - 7/8" - 1"

Heat exchangers freon / gas to liquid - BA-68-F series

Plate Heat Exchangers - designed for use with gas-liquid media - also known as Freon heat exchangers.

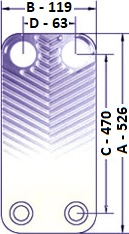

Nordic Tec's Freon plate heat exchangers ( FPHE ) from the Ba-68-F series are based on a plate of 526x119mm. With these dimensions, every single plate of the device provides a heat exchange surface area of approximately 0.068m². These plates are typically corrugated to enhance heat transfer efficiency, traditionally - in this question the solution is similar to traditional BPHE.

The gas-liquid plate heat exchanger Ba-68-F is conventionally equipped with two flow channels for media. The first channel is designated for Freon, gas, refrigerant, etc. It is easily identifiable by its characteristic gas connections, designed for brazing, which are 7/8" tubes.

The second channel is intended for liquid media, typically water or a glycol-water solution, at least in heat pump solutions. It has a standard external thread in a 1" size.

The most significant structural feature of the Freon heat exchangers Ba-68-F, distinguishing them from traditional liquid-liquid plate heat exchangers, is their increased resistance and durability under high pressure. As we know, Freon and similar media tend to operate at much higher pressures than the typical 20-30 bar. The working pressure for gas-liquid models is specified at max. 45 bar, with each unit undergoing pressure tests at a level of 60 bar. Maximal allowable working pressure of 4.5 MPa is enough to service most of the heat pumps freon applications or similar ones.

Gas heat exchangers from this series can also be equipped with optional thermal insulation, available for purchase together with the heat exchanger.

Gas Heat Exchanger Nordic Tec Ba-68-70-F 4,8 m²

Soldering Nipple Adapter for Heat Exchanger: 7/8" Pipe | 1/4" SAE

Soldering Nipple Adapter for Heat Exchanger: 7/8" Pipe | 3/8" SAE

Soldering Nipple Adapter for Heat Exchanger: 7/8" Pipe | 1/2" SAE

Soldering Nipple Adapter for Heat Exchanger: 7/8" Pipe | 5/8" SAE

- - Check as well the smaller series of refrigerant condensers Ba-26-F - heat exchangers by Nordic tec for heat pumps