PHE Plate Heat Exchangers

Plate Heat Exchangers by Nordic Tec

PHE or Plate Heat Exchanger by Nordic Tec we offer in many variants, our offer includes more than 150 models of heat exchangers.

They differ according to different parameters, such as the surface of the plate, the number of plates, connections, pressure resistance, volume or flow.

Most of our models can also be ordered with accessories, which distinguishes our offer and saves time.

We invite you to familiarize yourself with the following series of heat exchangers:

- PHE Ba-12 - The smallest series with a 191x73mm size plate, mainly with a 3/4" connection

- PHE Ba-16 - The series with a 220x90mm plate, with connections always in size 1 "

- PHE Ba-23 - One of the most popular series, with a plate size of 315x73mm and a connection of 3/4 "

- PHE Ba-32 - The most popular, key series, the most recognizable one. Plate size 286x116mm and connection 1 "

- PHE Ba-27 - The series which is a copy of the previous one, with a twin plate, but with a 1/4 "connection

- PHE Ba-60 - The larger series of exchangers, used in larger installations and in industrial use. Plate size - 526x124mm and connections in sizes 1 1/4 "or 1 1/2".

- PHE Ba-95 - The industrial series in size 616x191mm, with connections 2"

- PHE Ba-115 - Like the above, the series is a large row of size, for use in very large facilities. The size of the plate is 535x253mm, with 2".

The heat exchanger shop - Norditec-store.com - wide selection, high quality

Nordictec-store.com is a heat exchanger shop offering a wide selection of high-quality products. A heat exchanger is a device used in central heating and anywhere that energy needs to be transferred in the form of heat. It is increasingly used in solar installations, various types of boilers including condensing ones, and heat pumps. Nordictec-store.com offers many solutions tailored to the individual needs of customers, from small PHE units for small heating circuits to larger industrial systems. Our shop provides high-quality products and professional advice when choosing the right heat exchanger. By using the latest technology, we can offer exceptionally efficient and cost-effective devices. Choosing the Nordic Tec brand guarantees satisfaction with your purchase and solid technical support. We invite you to check out the models available in our offer!

Heat exchangers - basics, advantages, benefits, applications

A plate heat exchanger (PHE), sometimes known as a gasketed or brazed plate heat exchanger - is a device that enables the heat transfer between two media with different temperatures without contacting. Its design consists of thin, twisted or soldered steel plates that are stacked together. Depending on the operating conditions, spatial possibilities, and individual user requirements, the heat exchanger construction may differ slightly - it can consist of a varying quantity of plates with different thicknesses and surface areas.

If you're wondering why it's worth using a heat exchanger in a heating system, it's worth noting its high resistance to damage - even in extreme temperature and pressure conditions a plate heat exchanger works efficiently and maintains its original parameters for a long time (in fact for manyn years if it is sized properly). Furthermore, by using a heat exchanger, you can significantly increase the efficiency of the heating system, enabling effective cooperation between the heating and installation systems. If we add the fact that heat exchangers made of stainless steel work effectively with both fluids (glycol, water) and gases (air), we can conclude that this is a solution characterized by high usability, which finds application in many areas of life.

Plate heat exchanger - how it works. Heat Exchanger working principle

The working principle of plate heat exchangers is closely related to their structure. The device consists of two circuits (two separate channels) - the first one with a hot medium, supplied by a water jacket fireplace or a district heating network, a heat pump (examples can be numerous), and the second one with a low-temperature medium, such as radiators or underfloor heating. The operation of the heat exchanger consists of transferring thermal energy from the hot medium to another. The steel plates used to build heat exchangers effectively transfer thermal energy, as a result of which heat easily passes from the medium with a higher temperature to the medium with a lower temperature without the need for the two media to mix.

Plate heat exchanger application

Heat exchangers can be used, utilizing the above-described operating principle, in many applications. The most common and closest to an average person is the a plate heat exchanger usage in a central heating installation, in which it separates the installation of heating devices operating in a sealed system (e.g. gas boilers, heat pumps) from devices operating in an open system (e.g. a fireplace with a water jacket).

A similar situation occurs, for example, when a part of the installation needs to be filled with non-freezing liquid (glycol) and this part needs to be separated so that it does not mix with the water from the rest of the installation, but so that both parts can transfer heat to each other. The described situation often occurs when connecting heat pumps to heating systems. Therefore, due to the increasing popularity of heat pump heating, plate heat exchanger for heat pumps is becoming more and more widely known device.

The above describes only a small spectrum of plate heat exchanger applications. Actually, there are many more, including refrigeration, but it is impossible to list them all here.

The efficiency of plate heat exchangers

Taking into account the principle of operation of plate heat exchangers described above, it is easy to conclude that they are passive devices that do not generate thermal energy, but only transfer it to other elements of the system. The effectiveness of heat exchangers is influenced by the following factors:

- The plate arrangement in a heat exchanger - the plates in the heat exchanger should be arranged in a counterflow configuration (to achieve as much efficiency as possible)

- Total area of a plates of a heat exchanger - the larger the surface area, the higher the efficiency of the device. In order to avoid the need for huge plates, corrugated plates are used. The plate surface area (also known as the heat transfer surface area) is the most important factor affecting efficiency

- The number of plates in a heat exchanger - the higher the number of plates, the higher the efficiency of the device, at least when comparing devices with a similar single plate surface area.

Plate heat exchangers - types and applications

Taking into account the method of plate connection in heat exchangers, there are two types of devices available on the market:

- Brazed plate heat exchangers or BPHE for heating/cooling systems - the plates in the exchanger are joined together by soldering. The advantage of this type of device is the fact that it does not take up much space while maintaining high efficiency.

- Gasketed plate heat exchangers for heating systems - the plates in the PHE are connected to each other using a frame. The use of gasketed PHE is less common than the use of brazed plate heat exchangers. These are often bigger devices for industrial applications.

Installation of Heat Exchanger in central heating

The use of a plate heat exchanger in a central heating installation is particularly justified when we want to create two independent circuits - an open one with the heating boiler (or another heat source) and a closed one with the installation components. Considering that manufacturers of heating fittings often require their products to operate in a closed circuit, the use of a heat exchanger between them and the boiler operating in an open circuit is necessary. Similarly, underfloor heating should operate in a closed circuit, and therefore must be separated from the open circuit heating devices.

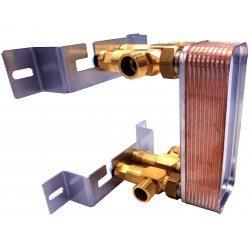

The method of installation of a plate heat exchanger depends primarily on the type of device itself. However, it is important to always remember to provide adequate space around the heat exchanger to allow for maintenance and cleaning tasks. During installation, the device should be properly stabilized, and the individual circuits should be connected correctly, with the counter-current flow maintained. Detailed information regarding the installation of plate heat exchangers can be found in the manufacturer's instruction manual included with the product.

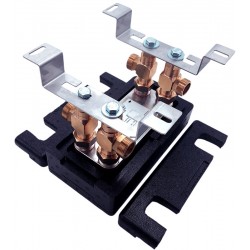

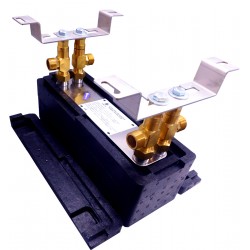

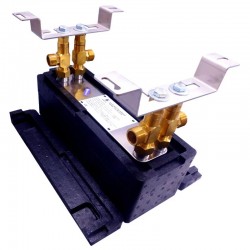

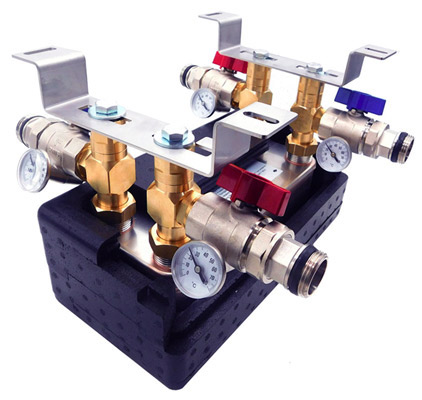

Consider using pre-made wall brackets for a heat exchanger offered by Nordic Tec for installation purposes. You can find them in our catalog.

Plate Heat Exchangers and Higher Operating Pressure

A plate heat exchanger can also be designed for gaseous media, although in such cases it undergoes a different technological process to ensure greater pressure resistance. Such a plate heat exchanger can achieve a pressure resistance of up to 45 bar – Freon-compatible heat exchangers can also be found in the Nordic Tec catalogue.

The standard models intended for use with liquids typically have a maximum operating pressure of 10, 20, or 30 bar.