Plate heat exchangers - selection based on exchange surface area

As we know, a plate heat exchanger is a device designed for heat exchange between two mediums. This solution finds applications in industrial installations as well as residential buildings. Plate heat exchangers are installed in various systems, including gas and solid fuel boilers, water jacketed fireplaces, and heat pumps. Few people realize that they are also used in refrigeration, for example, in breweries for cooling wort before adding yeast. Plate heat exchangers are among the solutions that enjoy great popularity in the market.

Heat transfer area of a heat exchanger - is it helpful?

In our store, you will find a wide selection of plate heat exchangers - but the key to proper operation of this device is always the correct selection, based on the fundamental and reliable parameter, which is the heat transfer area ( or simply the total surface area of the plates ). Considering that plate heat exchangers of various capacities are used depending on individual user needs, to facilitate the selection of the appropriate model, we have grouped the devices available in our store into categories according to the heat exchange surface area. Devices with low power are recommended for small central heating systems or for supplying installations, such as separate heating circuits. On the other hand, the largest of the devices we offer, with a surface area above 5-10 m², will perform well even when supplying multi-family buildings, industrial halls, warehouses, etc.

The biggest plate heat exchangers from our catalogue have cca 15m² of plate surface.

Size a heat exchanger on Nordictec-store.com - using a heat transfer surface area

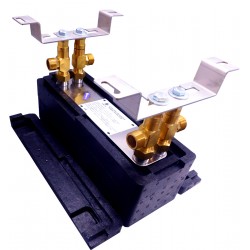

Nordictec-store.com offers a wide range of plate heat exchangers to suit various heating needs. Plate heat exchangers are constructed from a series of plates connected through soldering or twisting. Made from materials with excellent heat conductivity, these heat exchangers effectively transfer thermal energy between mediums without mixing them. The key role in this process is played by the temperature difference, which drives the flow of thermal energy within the device. The working fluids flow through the plates of the heat exchanger, resulting in the exchange of heat: the fluid at a lower temperature is heated while the fluid at a higher temperature is cooled.

Our online store Nordictec-store.com provides a diverse selection of plate heat exchangers with various total heat exchange surface areas. The surface area of the smallest models offered by us is less than 0.5 m², while the largest models can have surface areas of several square meters or more. If you are unsure about which plate heat exchanger to choose, please don't hesitate to contact us – we're more than happy to assist you in selecting the best solution for your needs.

Heat exchangers - versatile devices with widespread applications

Heat exchangers are utilized across various industries such as refrigeration , air conditioning, paper manufacturing, refining, and ... many others. There exist different types of heat exchangers, including plate, tubular heat exchangers, condensers, evaporators, and many more. Heat exchangers are crucial components in energy-saving processes as they can conduct heat exchange more efficiently and economically than traditional methods.

By using heat exchangers those processes require less energy, thus being more environmentally friendly. Therefore, heat exchangers are "employed" in numerous modern technologies to achieve greater efficiency and productivity. Their impact is particularly significant in the fields of material production and processing, food processing, and chemical industries. In summary, heat exchangers are indispensable in today's world and play a crucial role in various industries. Their importance cannot be overstated.

The principles of selecting a heat exchanger - what is the heat transfer surface?

A heat exchanger is a device used to transfer heat from one medium to another - as we all already know. To ensure effective heat transfer between these 2 mediums, the heat transfer surface is one of the key factors to consider when choosing the right heat exchanger. The heat transfer surface is the total surface area of plates of our PHE - through which heat flows between the two mediums. It is simply the sum of the surface areas of all the plates in the heat exchanger, that's simple. The larger the exchange surface, the better the efficiency of heat exchange. To increase the exchange surface area for thermal energy in the heat exchanger without increasing the dimensions of the device itself, specially profiled plates are used.

How large of a plate heat exchanger to choose for specific applications?

When choosing a plate heat exchanger for specific applications, the selection should be based on various factors including temperature, flow rates of the fluids, and their physical properties. However, selecting the appropriate exchange surface area is crucial for ensuring efficient heat transfer and achieving desired results. The size of the heat exchange surface area needed for a particular heat exchanger depends on its intended use. As a rough estimate:

- Plate heat exchangers for gas boilers should be selected so that there is a minimum of 0.30 m² of heat exchange surface area for every 10 kW of gas boiler capacity.

- Heat exchangers for other central heating boilers should be chosen so that there is a minimum of 0.25-0.30 m² of heat exchange surface area for every 10 kW of heating boiler capacity.

- Plate Heat exchangers for heat pumps (connecting them to the heating system) should be selected so that there is a minimum of 1.50 m² of heat exchange surface area for every 10 kW of heat pump capacity in situations where the primary heat emitters in the heating system are radiators, or a minimum of 3.0 m² of heat exchange surface area for every 10 kW of heat pump capacity in situations where the rooms are heated entirely by underfloor heating.

- Heat exchangers for electric and electrode boilers should be chosen so that there is a minimum of 0.30 m² of heat exchange surface area for every 100 m² of heated building area for older or well-used installations, and a minimum of 0.25 m² for newer installations.

- Heat exchangers for home brewing should be selected based on the planned size of each batch. For example, if brewing 20-25 liters of wort, a heat exchanger with a surface area of 0.4-0.5 m² will suffice, while producing 45-50 liters of wort may require a heat exchanger with a surface area of even 0.9-1.0 m².

Completely different methods are used when the heat exchanger must work with a refrigerant, for example as a condenser of a heat pump. We have such solutions in our catalogue too - just contact us.

What to pay particular attention to when selecting a heat exchanger?

The fundamental consideration - when purchasing a heat exchanger is the previously mentioned heat exchange surface area of the exchanger. Additionally, several other factors should be taken into account when selecting a heat exchanger. These include determining the type and characteristics of the medium to be cooled or heated . It is also necessary to adjust the flow and temperature of the cooling medium to meet process requirements. Another important consideration is checking the suitability of the heat exchanger for the specific environment and determining the maximum working pressure. Consideration should also be given to the ease of cleaning and maintaining the heat exchanger , as well as the space required for its installation. Energy efficiency and cost-effectiveness of the heat exchanger are also crucial aspects that impact the overall feasibility of the process.

Therefore, when selecting a heat exchanger, it is essential to pay close attention to technical parameters, as well as the costs associated with its operation and maintenance.

What materials are our plate heat exchangers made of?

The plate heat exchangers available at Nordictec-store.com online store are manufactured from 316L stainless steel brazed with 99.9% copper (Cu), making them well-suited for various applications. Stainless steel is among the most popular materials used in plate heat exchanger production. It is corrosion-resistant and a good conductor, making it suitable for heat exchangers intended for operation in aggressive environments such as hot water, steam, and chemical substances. Meanwhile, copper is a highly durable bonding material, which is why it is commonly used in the production of heat exchangers for central heating systems.

Purchasing a plate heat exchanger directly from the manufacturer - benefits

Buying a plate heat exchanger directly from the manufacturer comes with many advantages. 1-ly, we have the assurance that the purchased product is original and meets all quality standards, as well as the manufacturer's full support in case of any technical assistance needed. Secondly, we avoid additional costs from intermediaries or distributors, meaning we pay for the product itself rather than for intermediation in its sale. Thirdly, the waiting time for orders is significantly shorter since there is no need to transport the product through various distribution stages.

Finally, by buying directly from the producer, we have the opportunity to obtain favorable payment and delivery terms. So - by opting to purchase a plate heat exchanger directly from the manufacturer, we gain confidence in quality, save money and time, and also have the opportunity to obtain favorable conditions.