Low Loss Headers - Hydraulic Separators

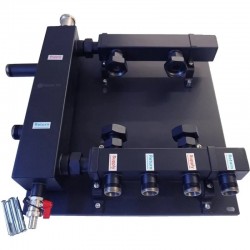

Steel low loss headers for balancing heating systems

Hydraulic separators - or stainless steel low loss headers for central heating installations that are designed to balance pressures, flows, and temperatures in extensive heating systems. In some situations, the hydraulic separator can successfully replace heat exchangers, although it should be remembered that when using the separator, even though the system is divided, water mixing still occurs - therefore, it is not a device that can always be used as a substitute.

The offer includes low loss headers with different configurations of the number of outputs for heating circuits, most often with thermal insulation.

Some products from this category are the hydarulic separators kit, ready to install. You are welcome to browse our offer.

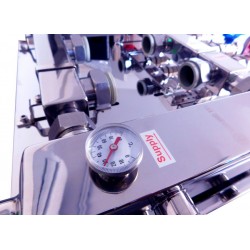

Low Loss Header-Separator with 2-circuit-Manifold 2 + Thermometer & Manometer (130mm)

Classic Low Loss Header for 2 circuits - 50 kW

Low Loss Header 50 kW with thermometer & manometer

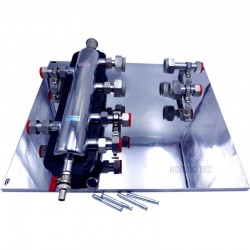

Low Loss Header Hydraulic Separator SNT25 for 3 circuits - 70 kW

Low Loss Header Manifold 2 with Thermometer & Manometer

Low Loss Header - Manifold 3 with Thermometer & Manometer (for 130mm-Pump)

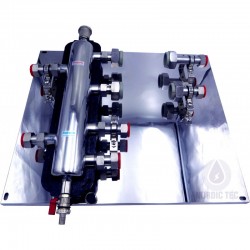

Low Loss Header with 3 heating cirlces manifold

Low Loss Header - Hydraulic Manifold Nordic Tec 2 + 2

Hydraulic Separator SNT25 on the plate

Low Loss Header-Hydraulic Manifold 3 circuits for 3 pumps

Low Loss Header for central water heating systems

Modern heating systems often use various heat sources and are equipped with diverse heat receivers. Additionally, each circuit in the heating system typically has its own circulation pump. With the needs of users in mind - we have expanded our store's offerings to include low loss headers - hydraulic separator bottles for central heating, enabling parallel operation of all circuits to ensure that the circulation pumps do not interfere with each other's performance. By choosing the models available in our catalogue - you will acquire high-quality products - that will provide reliable operation for a long time. We warmly invite you to browse our products.

Hydraulic water separator or low loss header? Nordictec-store.com

The online store - Nordic Tec Europe - offers a wide selection of hydraulic water separators for central heating. We provide insulated low loss headers and separator in a set with distributors (heating manifolds dividing heating circuits) of various operating parameters. Our products are made of high-quality materials, ensuring reliability and long lifespan. Additionally - we offer competitive prices and fast and secure shipping to every place in Europe - thanks to our stocks in 3 european countries. Purchasing low loss headers by Nordic Tec guarantees satisfaction and professional hydraulic separation of your heating system. Our team of specialists is available to provide expert advice in selecting the appropriate device and offers support throughout the purchasing process.

Hydraulic separator - low loss header - the operation principle

Low loss header is a device used in heating systems to separate the boiler circuit from the heating circuit. It is used in heating systems consisting of one or several heating circuits (e.g., gas boiler, heat pump) - and multiple heat receiving circuits (radiators, underfloor heating, domestic hot water - DHW etc), each equipped with its own circulating pump. The central heating coupling - which is our low loss header - allows maintaining proper pressure between the boiler circuit and the heat receiving circuits, ensuring optimal temperature in the system. The inside of the tube is empty, allowing the working fluid to flow in all directions. The operation of the water hydraulic separator is regulated by pumps and valves.

The hydraulic separator is a header connected to supply and return pipes from the boiler side and the heating system side. The water circuits are thus separated , but the working fluid from the individual circuits mixes in the heating coupling chamber (steel tube - the main separator's body - low loss header bottle). The purpose of using this kind of coupling is to support the cooperation - between the boiler and the receiving system - which is particularly important when the flow rate in the heating system significantly deviates from the boiler side.

The functioning varies depending on the usage conditions:

- When the heat demand from the heating system is equal to the energy - generated by the boiler, the circulation of the heating fluid takes place directly from the connections supplied by the source to the heating supply circuits.

- When the heat demand from the heating system is lower - than the heat production on the boiler side, the heat source automation receives a signal to reduce or turn off the heat production and it responds by reducing the power or shutting down one of the devices.

- When the heat demand from the heating system is higher - than the heat production on the boiler side, the heating circulation pumps draw a portion of the heating fluid flow in the coupling, and the control system receives a signal of increased heat demand, resulting in an increased energy production.

Low loss headers - where to use in a heating system?

Hydraulic separation by low loss headers for central heating is installed between the heat source (boiler, heat pump, fireplace etc.) and the heating or cooling system. Its installation is recommended in the following three situations:

- When the installation requires at least one additional circulating pump, and the receiving system consists of at least two heating circuits

- When there is a need to protect the receiving system from excessive temperature

- When there is a need to protect the heating boiler from a return temperature that is too low

Benefits of using a water separator in a central heating system

Benefits of using a hydraulic separation in a central heating system include:

- Increased boiler or other heat source lifespan - thanks to protection against low return temperatures and prevention of low-temperature corrosion

- System flushing and air purging - resulting in improved comfort and usability of the heating system.

- Extended and longer lifespan of circulation pumps.

- Faster response from control automation.

- Elimination of the need for additional system adjustments

How to size a low loss header? Hydraulic separator sizing

Choosing a hydro separator - so low loss header for a central heating system is one of the simplest tasks and can often be done successfully by individuals outside the industry as well. When selecting a hydraulic coupling for central heating, it is worth considering the following parameters:

- Maximum power of the heat source / in kW

- Maximum flow rate of the heating system.

- Diameter of the system's connections - 3/4" - 1" - or 1 1/4" (in most cases)

_________________________

Check as well the other categories of product by Nordic Tec: