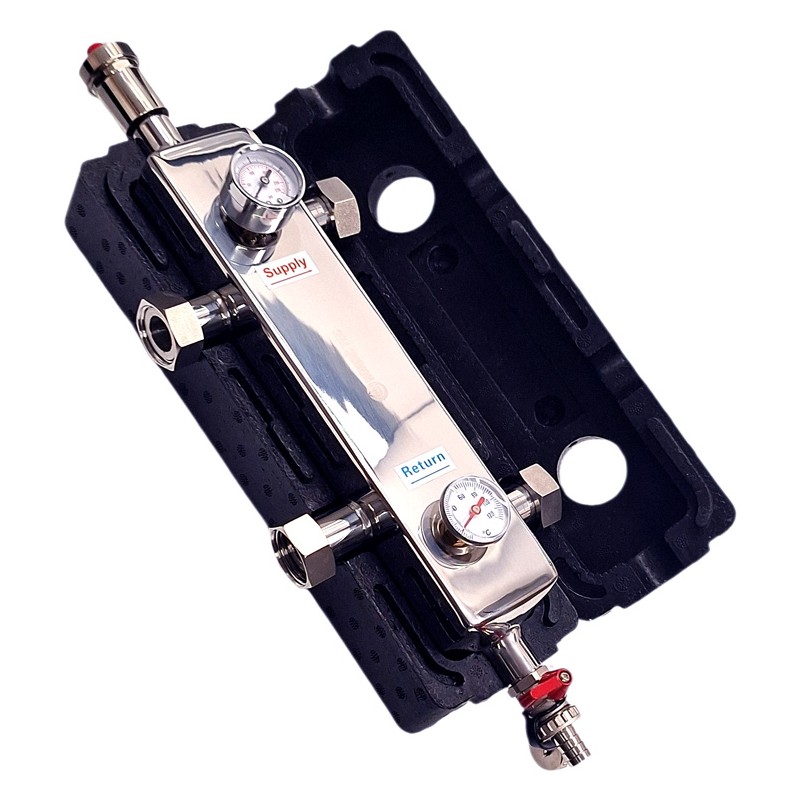

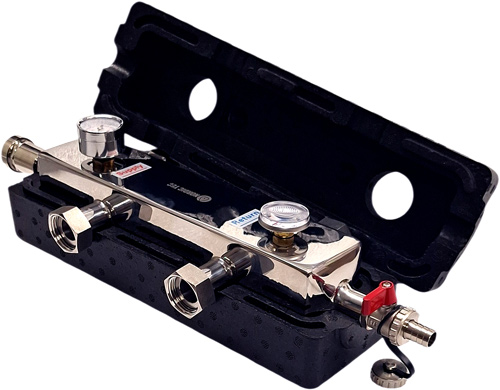

Low Loss Headers - Hydraulic Separators

Low Loss Header 50 kW with thermometer & manometer

NORDIC TEC Hydraulic separator - Low Loss Header SNT-A-70 for heating

Low Loss Header - Hydraulic Separation system with thermal insulation

with thermometer & pressure gauge

- Low Loss Header designed for connecting 2 circuits on 1" (DN25) size.

- Hydraulic Separation set equipped with temperature measurement (thermometer) and pressure measurement (manometer / pressure gauge).

- Fitted with a drain valve and an air vent valve (included)

✅ Wide catalogue of low loss header and hydraulic separator, also on mounting pleates (ready sets)

☑️ Quick delivery in every European country.

✅ Free delivery in: FR, IT, ES, DE, PL, SI, AT, DK, NL, BE, CZ, LV, EE, LT

Reference: SNT-A-70

Condition New

Hydraulic Separator - Low Loss Header DETAILS:

- Maximum recommended installation capacity: up to 50 kW.

- Maximum recommended flow rate: up to 4.2 m³/h.

- Connection size with nut: 1" internal thread.

- Connection sizes for drain valve and air vent valve: 1/2".

- Maximum recommended operating temperature: <90°C.

- Maximum safe working pressure: up to 10 bar.

- Construction: Stainless steel + galvanized steel.

- Thermal insulation for heat loss reduction: Expanded polypropylene foam (EPP).

- Wall mounting elements are included in the set

The principle of operation of a low loss header for central heating

Generally the principle is to automatically balance the pressure between two circuits in the heating system...

The purpose of this low loss header is to mix the fluids that come into it from two independent circuits inside its steel body. The mixing itself is not the goal, but it leads to balancing the pressure in the central heating system in both connected circuits. This provides a balanced installation, which is crucial for the economic operation of heating devices, particularly gas or electric boilers, as well as circulation pumps . Additionally, pressure balancing results in lower wear and tear on this type of equipment.

The balancing of the working pressure in the installation occurs because the inlets on the low loss header body - called as well the hydraulic separator - are not aligned (in relation to each other). As a result, mixing occurs spontaneously, so there is no need to use additional partitions or screens in this type of hydraulic separator.

Mounting the hydraulic separator in a boiler room

Mounting of the hydraulic separator can be in a vertical or horizontal position. However, we recommend mounting our low loss pressures vertically, because this position allows you to use accessories such as a vent and a drain valve with a tap - which is impossible in the horizontal position.

Hydraulic Separator with Thermometer – Underfloor Heating | Nordic Tec

The hydraulic separator with thermometer and manometer is a versatile product used in heating systems. It is designed to regulate the water flow between different heating circuits while simultaneously providing important information about temperature and pressure. Measuring temperature and pressure—through the presence of a thermometer and a manometer—can be particularly useful when the hydraulic separator is used in conjunction with underfloor heating systems.

The heating separator for two heating circuits acts as a distributor, controlling the water flow and enabling the heat energy to be evenly distributed to different parts of the system. Thanks to the integrated thermometer, the water temperature can be monitored in real time, allowing precise control and adjustment of the heating output according to current requirements.

The manometer, in turn, measures the pressure within the heating system. It provides information about the pressure condition and makes it possible to detect any pressure fluctuations or pressure-related issues. This allows potential faults to be identified and resolved at an early stage, ensuring smooth and efficient operation of the heating system.

The hydraulic separator with thermometer and manometer is a valuable tool for installers and operators of heating systems. It enables precise monitoring and control of system performance in order to ensure optimal operation and energy efficiency. Thanks to the information provided by the thermometer and the manometer, potential problems can be detected and addressed early, ensuring reliable and comfortable heat delivery.

The hydraulic separator and its immediate surroundings are also a suitable place for the installation of dirt separators, provided that these are required in the respective system.

SNT-A-70

429 Items

New

No reviews

You might also like