Low Loss Headers - Hydraulic Separators

Low Loss Headers - Hydraulic Separators

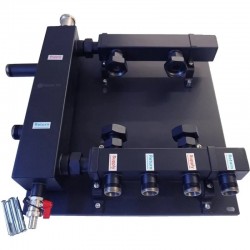

Low Loss Header Hydraulic Separator SNT25 for 3 circuits - 70 kW

Low Loss Headers - Hydraulic Separators

Low Loss Header with 3 heating cirlces manifold

Low Loss Headers - Hydraulic Separators