Low Loss Header for central heating, e.g. in heating systems with a gas boiler and underfloor heating

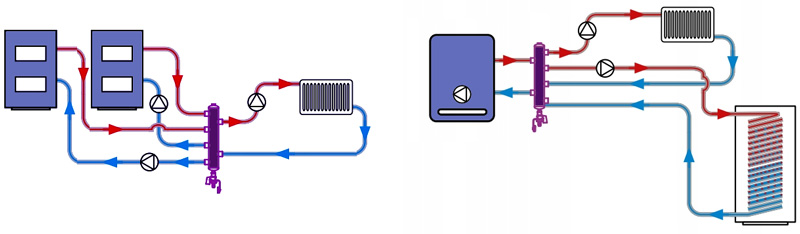

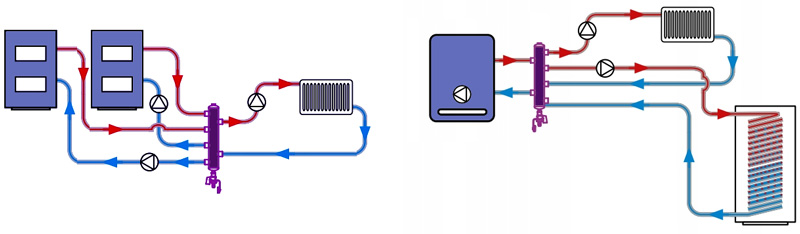

In heating systems with both underfloor heating and radiators, a hydraulic separator - low loss header with 2 heating circuits (and of course a heat supplying circuit) allows for connecting two independently regulated sections, each of which can have its own circulation pump. In this case, the coupling not only balances the flow (the installation would often exceed the flow rate achievable by the boiler pump) on both sides, but also serves as a distributor, creating three circuits - one on the heating side (condensing boiler) and two additional receiver circuits (radiators and underfloor heating).

Additionally, by mixing water in

the hydraulic separator steel chamber, we ensure that the water returning to the boiler is not excessively cooled, which is not beneficial for modern boilers (known as

cold return).

Advantages of using a hydraulic separator in home heating system:

- No hydraulic interaction between the supply and heating circuits

- Suitable for both single and multiple-boiler installations.

- Flexibility in the use of control systems.

- Easier sizing of the pump in the boiler circuit.

- Easier selection of control valves.

- Protection against low-temperature corrosion.

Schema of connecting the low loss header 70 kW in a installation with 2 heat sources (boilers) and with 1 heating source (condensing boiler) for central heating and domestic hot water