Plate Heat Exchanger NORDIC Ba-16-24 1" 100kW

Plate Heat Exchanger NORDIC TEC Ba-16-24

100 kW heat exchanger – nominal power at high industrial parameters. A flow-through, counterflow device for heat exchange from a so-called heat source to the opposite circuit. Designed for use in heating or refrigeration systems.

- Plate Q'ty: 24 pcs.

- Connections: 1" BSP

- Heat Exchange Area: 0.384m²

☑️ Fast delivery of a plate heat exchanger in the most European countries

✅ Free delivery in the following countries:

IT, ES, FR, AT, DE, NL, PL, DK, CZ, BE, LT, LV, SI, EE

Reference: NT Ba-16-24

Condition New

HVAC Heat Exchanger - Nordic Tec Ba-16-24 - 4x 1", 24 plates

Nordic Tec Ba-16-24 Plate Heat Exchanger 30 kW

1" connections, 24 plates

Technical details - HVAC HVAC Heat Exchanger - Nordic Tec Ba-16-24:

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 1", BSP

- Working Pressure - <20 bar

- Test Pressure - 40 bar

- Max. temperature +230°C

- Flowrate - 8 m³/h

Heat Exchange Surface - HVAC Heat Exchanger - Nordic Tec Ba-16-24: 0.384 m²

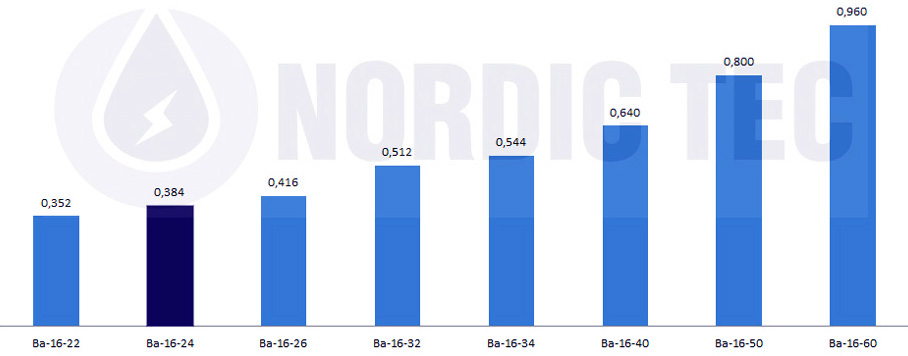

The Ba-16-24 heat exchanger, as seen in the graphic, has a plate surface area of 0.38 m². It remains one of the smaller heat exchangers in the Ba-16 series, which includes models ranging from 12 (Ba-16-12) to 70 plates (Ba-16-70). If you are interested in other heat exchangers for heating boilers shown in the graphic, you will also find them in our catalog.

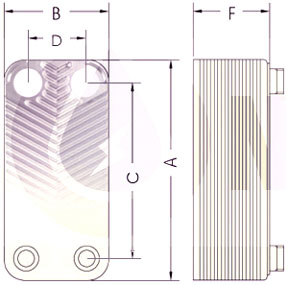

Dimensions:

(A) - 220 mm

(B) - 90 mm

(F) - 61 mm

(C) - 180 mm

(D) - 52 mm

________________________

Frequent queries from customers reffering to PHE Ba-16-24:

Is the Ba-16-24 heat exchanger suitable for working with a 15 kW fireplace?

Answer: Yes, it is a good choice if you need to connect a fireplace between 12 and 15 kW and 1" threads are required. In the case of water jackets heated by an open flame, fueled by wood or coal, it is recommended to use a ratio of 0.25–0.30 square meters of heat exchanger surface area (i.e., the total plate surface) per 10 kW of the device. This ratio includes oversizing, ensuring safe and reliable operation for years.

Can the Ba-16-24 heat exchanger clog?

Answer: Any plate heat exchanger that operates in a system for many years can become clogged. This is caused by scaling of the device, which is a normal aging process for hydraulic equipment. However, this rarely happens before 10–15 years of operation. It is also important to ensure that the heat exchanger is installed correctly, meaning it should have filters on the inlet of each side.

There is also a possibility of blocking the heat exchanger immediately during its installation if filters are not installed before the system’s trial run. In such a case, when the circulation pumps are started, impurities from the system may be drawn into the exchanger’s channels. However, this is a situation that an experienced professional is unlikely to encounter.

2338 Items

New

No reviews

You might also like