Plate Heat Exchanger NORDIC Ba-32-70 1" 385kW

Plate Heat Exchanger NORDIC TEC for Heat Pumps - Ba-32-70

The units size makes it predestinated for Heat Pumps mainly, but it can freely cooperate with all kind of traditional boilers as well.

- Plate Q'ty: 70 pcs.

- Connections: 1" BSP

- Heat Exchange Area: 2.240m²

Plate heat exchanger for monoblock/split heat pumps (water/water or water/glycol), as well as for traditional heat sources.

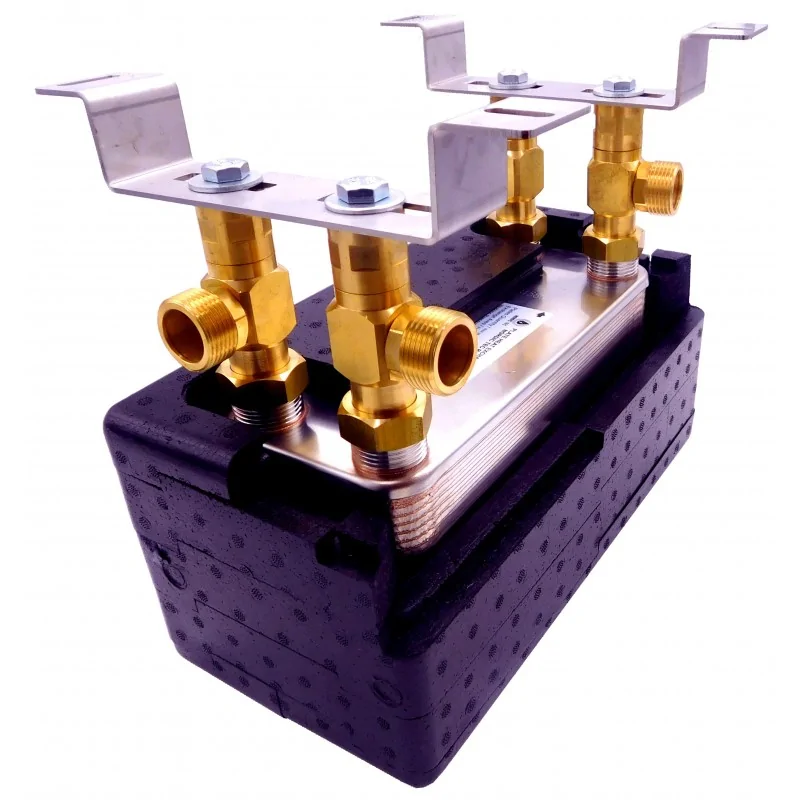

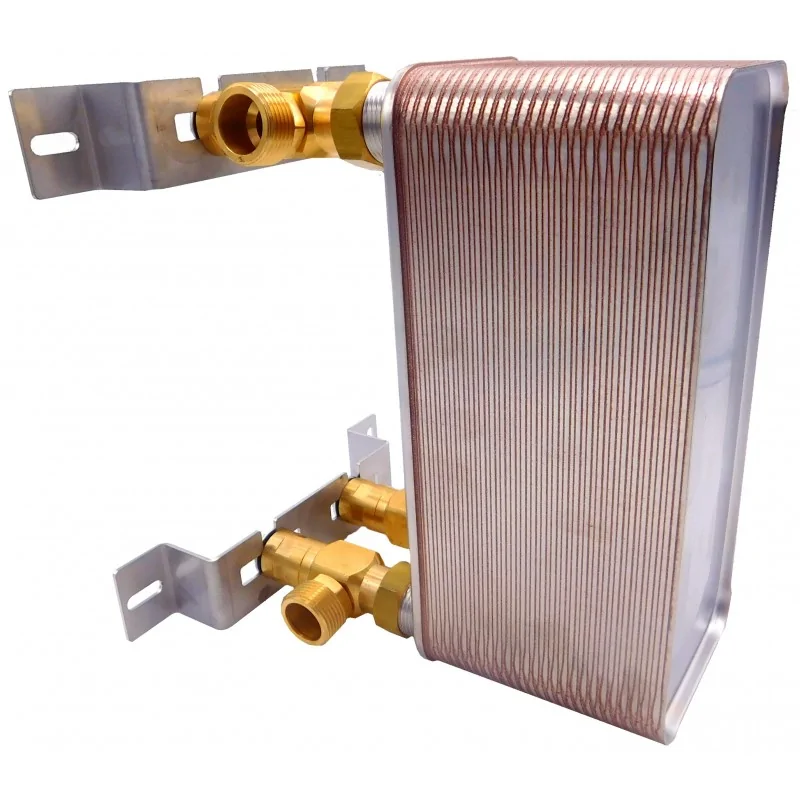

☑️ As an option - the possibility to purchase a Ba-32-70 PHE with insulation and a mounting kit (wall-mounting set with rotary fittings)

✅ Instant availability & Free delivery in: FR, IT, ES, DE, PL, AT, SI, DK, NL, BE, CZ, LV, LT, EE

Reference: NT Ba-32-70

Condition New

Heat Exchanger Nordic Tec Ba-32-70 - 4x 1", 70 plates

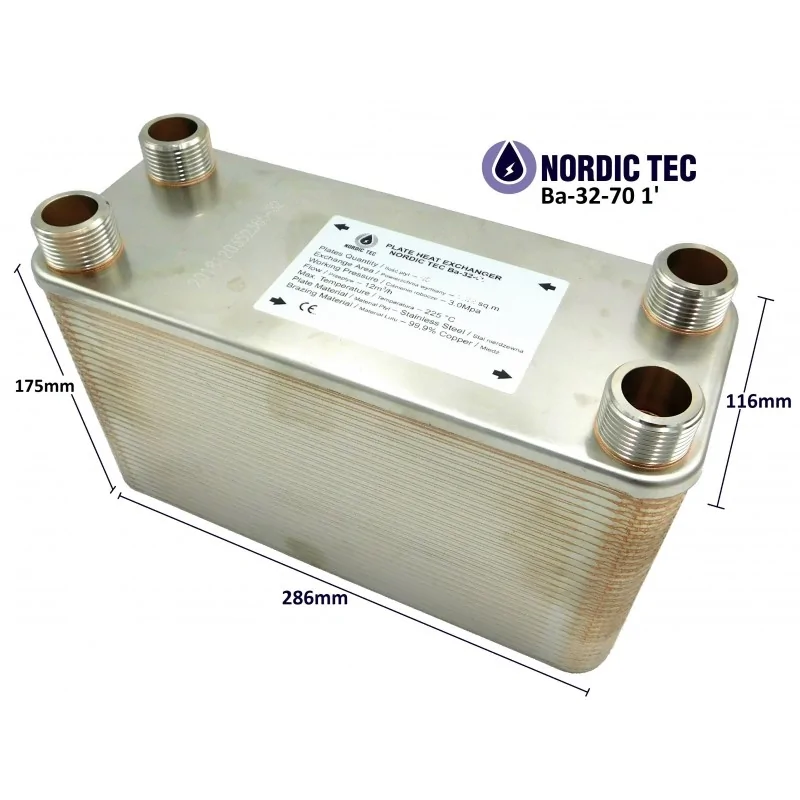

Technical details - Plate Heat Exchanger Ba-32-70:

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 1", BSP

- Working Pressure - <30 bar (liquid to liquid heat exchanger)

- Test Pressure - 45-60 bar

- Max. temperature +230°C

- Flowrate - 12 m³/h

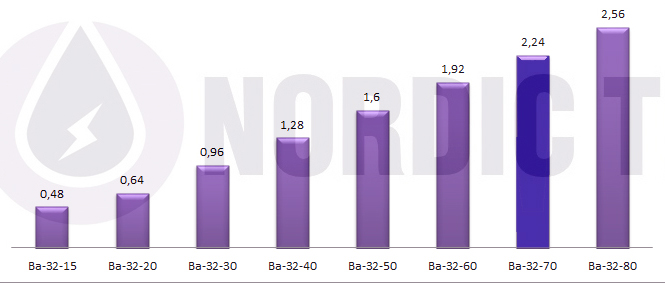

Heat Exchange Surface Area of a Heat Exchanger Ba-32-70 - 2.240 m²

The above graph illustrates a comparison of the heat exchange surface - or simply the active surface area of the steel plates in Nordic Tec Ba-32 heat exchangers, depending on the number of plates. The Ba-32-70 model has 70 plates, this way - creating a total surface area of 2.24 square meters. Below you will learn what this value means in practice - as the heat transfer surface area is the main factor determining the selection of a plate exchanger for a boiler or heat pump - or any other application.

In practice, it is the surface area of the plates that determines how many kW of power the boiler or heat pump can have - which will be properly handled by a specific model of a plate heat exchanger. The indicated surface area of 2.24 m² places this model as quite large and efficient, providing the capability to handle quite robust heat sources - as described below.

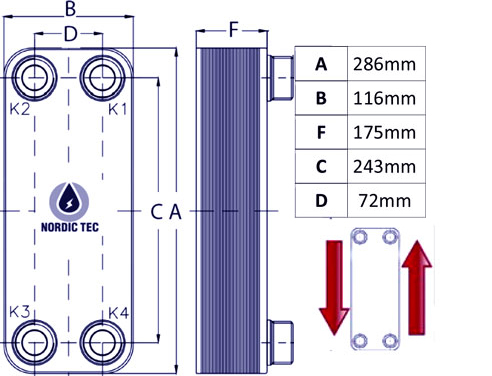

Dimensions:

The most common applications of the Ba-32-70 plate heat exchanger are:

- Heating installations with heat pumps using or not using a heat buffer , with options for glycol or water - suitable for heat pump capacities up to several kW, both for split and monoblock systems / heat pump heat exchanger

- Central heating systems with coal-fired boilers up to approximately 70 kW / for coal-fired boilers.

- Systems with eco-coal-fired boilers up to around 70 kW - 80 kW ( combined - closed/open ) / heat exchanger for eco-coal-fired boilers

- Operating condensing boilers or multiple boilers in a cascade with capacities up to 60-70 kW, depending on the system parameters / heat exchanger for gas boilers

- Connecting pellet boilers for large facilities , e.g. , commercial buildings / for pellet boilers

- Preparing domestic hot water without using a water heater / domestic hot water heat exchanger

- Collaborating with glycol heaters for heating halls and warehouses / heat exchanger for glycol heaters

- Heating large properties such as hotels, shops , in cooperation with municipal district heating networks / for municipal district heating networks

____________________________________________

How to select a heat exchanger? | Ba-32-70 Nordic Tec

Due to the extensive range of applications for plate heat exchangers , there's practically an infinite combination of factors such as the types of media (each with their own specific heat capacity), flow rates, initial temperatures, cooling or heating objectives, and power in kW. Nordic Tec heat exchangers are compatible with various heat sources, boilers, fireplaces, and heat pumps . They can be used to heat both residential properties and larger spaces such as sports halls and public buildings. They are also suitable for cooling applications, working with most available liquid refrigerants like glycol .

It's easier to answer the question "How to select a heat exchanger" when you have specific information about the planned application, for example, in a heating setup, along with basic details about the intended use. If you're having trouble selecting a heat exchanger, it's best to rely on specialists and get in touch with us .

You're also welcome to visit our blog , where you can find more information about selecting heat exchangers, including those for gas boilers or pellet stoves. Additionally, there's an article discussing the potential consequences of choosing a heat exchanger that's too small for its intended purpose.

What does the symbol of the heat exchanger - Ba-32-70 - mean?

"Ba" is our designation for a vacuum-brazed heat exchanger , which is the classic plate model. The number in the middle represents the heat transfer surface area of a single plate, which is 0.032m². The number at the end signifies the number of plates in the exchanger - in this case, it's 70 plates . If you multiply the number of plates by the surface area of a single plate, you'll get the total surface area of the device, which is 2.24m². This provides a decent surface area suitable for various applications, including heat pumps, even with demanding low-temperature underfloor heating setups. This is just one example; all our plate heat exchanger symbols are based on this key format.

_________________________

183 Items

New

No reviews

You might also like