Pump groups & Pump stations

- New

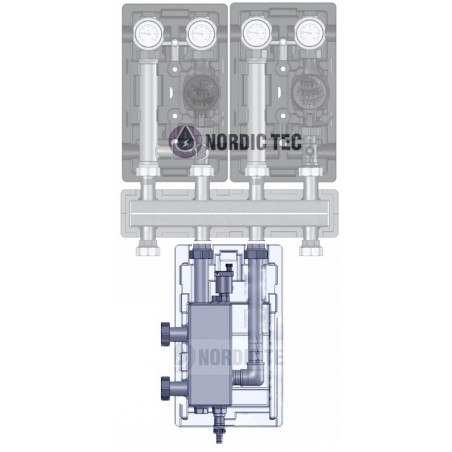

Boiler guard with Low Loss Header 1″ DN25 125 mm

Hydraulic Separator – Heating Low Loss Header 1 Inch Nordic Tec with Insulation and Pressure Gauge

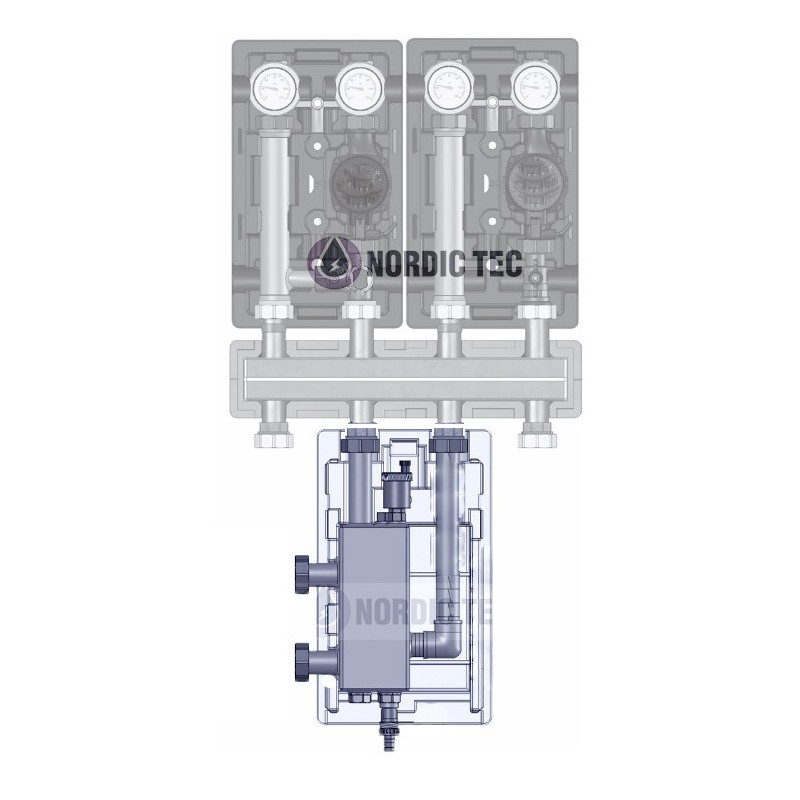

Hydraulic separator for pump groups and pump assemblies, designed to work with heating manifolds. The hydraulic separator is rated for systems up to 60 kW and intended for relatively small hydraulic installations. It functions both as a hydraulic separator and as a dirt separator, with settled contaminants removable via a drain valve.

- Heating low loss header for 1-inch systems (connections 1 1/2 inch); connection details provided below

- Hydraulic separator construction: painted stainless steel

- Hydraulic separator housing: welded, with flanged connections and union nuts

- The hydraulic separator is equipped with a pressure gauge for pressure measurement

- Air vent included in the set, located behind the pressure gauge

- Drain valve included

- Permissible operating temperatures up to 135 °C

- 2 additional connections at the bottom of the separator, factory-fitted with plugs

- Thermal insulation included

- Center-to-center distance (between connections), vertical and horizontal: 125 mm

☑️ Robust and durable hydraulic separator with solid insulation and a pressure gauge for manifolds and pump groups

✅ Free delivery within 14 European countries

Reference: Boiler-guard-NT-K-1

Condition

Connections of the hydraulic separator – the Boiler Guard by Nordic Tec

The connections of the device Boiler Guard - hydraulic separator included in this offer are configured as follows:

- Flow from the boiler and return to the boiler with a center-to-center distance of 125 mm – connection 1 1/2” (female thread)

- Heating flow and heating return also with a center-to-center distance of 125 mm – connection 1 1/2” (female thread)

The hydraulic separator is primarily intended for manifolds and pump groups from Nordic Tec. However, due to its standard dimensions and connection spacing, it is also very often perfectly suitable for boiler manifolds from other manufacturers.

What is the purpose of the Boiler Guard from this offer?

Boiler Guards are components of heating systems whose purpose is hydraulic separation. They act as separators between the heat source circuit and the heating circuits. Heat sources may include boilers, heat pumps, or other heat generators, while the consumer circuits may consist of underfloor heating or radiator systems. The operating principle of a Boiler Guard therefore corresponds closely to the function of a hydraulic separator – the terms are often used interchangeably.

What is hydraulic separation and why is it beneficial?

In practice, this means that the pump circuits on both sides of the hydraulic separator do not influence each other or “work against each other,” as this could lead to improper system operation. Each circuit should have its own flow rate and pressure level, independent of the other circuits. This ensures correct and efficient operation of boilers or heat pumps. Hydraulic separators, also referred to as heating low loss headers, are used precisely for this purpose.

It should be noted that while the hydraulic separator divides the system into two areas—two pump zones that are hydraulically separated in terms of pressure—the heating water still mixes inside the separator. Therefore, the hydraulic separator is not a heat exchanger that mechanically separates two circuits, but rather a device providing hydraulic separation.

Function of the heating low loss header in a heating system

The term “heating low loss header” is an industry-used, rather colloquial name for hydraulic separators. It rarely appears in technical documentation but is widely used in practice. The name derives from the function of the device, which is to prevent undesirable phenomena in heating systems.

The functions of the heating low loss header include:

- Stabilization of flow rates within the system

- Protection of the heat source against excessively low or excessively high flow rates

- Improvement of even heat distribution (no under-supplied heating circuits)

- Reduction of short cycling of the boiler or heat pump

- Limitation of the so-called cold return

- Air venting and separation of contaminants

The hydraulic separator – Boiler Guard is a multifunctional device

The hydraulic separator – Boiler Guard is a multifunctional device that combines the separation of air and gases with the removal of impurities and deposits. The product is available in a version with a hydraulic separation function, designed to divide flow rates between the boiler and the heating circuits, as well as in a variant without hydraulic separation.

Air separation function

The Boiler Guard also acts as an air separator – the heating water supplied from the boiler is directed onto an impact plate, which slows down the flow in the upper part of the device. In this zone of reduced turbulence, the contained air bubbles can freely rise upwards and accumulate.

At the same time, the return water flowing back from the heating circuits releases the air it contains through perforated elements that guide the gases into the collection chamber located in the upper part of the device. The air is continuously discharged to the outside via an automatic air vent, visible in the product images. In the standard configuration, it is positioned after the pressure gauge, although their order can be changed.

Hydraulic separation function

The supply water coming from the boiler is introduced into the device via a flow straightener. Depending on the current flow demand, the water is directed either to the heating circuits or – through perforated separation plates – directly to the boiler return.

The resulting hydraulic separation creates a zone that is neutral with respect to dynamic pressure conditions. The perforated separation plates reduce turbulence and ensure correct temperature stratification with a low overall installation height.

Function of removing impurities and deposits

The water returning from the heating system is deflected onto an impact plate, which calms the flow inside the device. The impurities and deposits contained in the water settle at the bottom and can be removed via a drain valve located in the lower part of the unit. The drain valve is also visible in the product images and is installed in one of the connections specifically prepared for this purpose.

Additionally, it is possible to integrate a magnetite separator in the form of a magnetic insert, to which ferromagnetic particles and magnetite circulating in the heating system adhere. For cleaning, it is sufficient to remove the magnets – the deposits then settle at the bottom and can be flushed out through the drain valve. Since the magnets are mounted in protective sleeves, the system remains closed and can stay filled with water.

The magnetic insert is not included in the delivery, however dedicated connections are prepared for this purpose and are fitted with plugs (blanking caps) in standard operation.

Boiler-guard-NT-K-1

11 Items

No reviews

You might also like