Thermal Insulation IZ-Ba-32-50 / IZ-Ba-27-50

Thermal Insulation Box IZ-Ba-27/32-50 for Heat Exchangers

Material: Polipropylen

Insulation box for PHE - dedicated for NORDIC TEC heat exchangers:

- Plate Heat Exchanger Ba-27-40 (286x116mm, 40-plate)

- Plate Heat Exchanger Ba-27-50 (286x116mm, 50-plate)

- Plate Heat Exchanger Ba-32-40 (286x116mm, 40-plate)

- Plate Heat Exchanger Ba-32-50 (286x116mm, 50-plate)

The product fits for heat exchangers by SECESPOL-Hexonic too - LB31-40 and LB31-50

Please note: We don't reply for questions about sizing insulation for exchangers by other brands.

☑️ Full catalogue of Nordic Tec plate heat exchanger insulation jackets

✅ Free delivery in: FR, IT, ES, DE, PL, AT, SI, DK, NL, BE, CZ, LV, LT, EE

Reference: IZ-Ba-27/32-50

Condition New

Thermal insulation / cozy for PHE Ba-32 and Ba-27 by Nordic Tec brand

The photoes are only commercial visualisation.

The insulation can have different ring quanity.

This insulation has 3 rings in fact.

This insulation has 3 rings in fact.

Information:

- Polipropylen thickness- cca. 24mm

- Maximal work temperature - 115°C

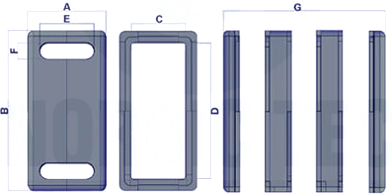

Dimensions of the product:

|

|

Do I always need an insulation for my heat exchanger? When I don't need the insulation for my PHE?

The insulation box for insulating a heat exchanger is a very good way to increase the efficienby of our cenral heating and in further perspective makes the heating more economic. But there exists as well the situtations when we don't need it. The PHE works like a small radiator, because it heats up the room when we put it. If we installaed the heat exchanger in a room where we don't have the radiators or floor heating and some temperature in this room is a good thing for us - we don't need to invest our money in thermal insulations.

Another application, in which typically we don't need to insulate the PHE - is a cooling system, especially if the unit works as a cooler in industry.

How an insulation box for a Nordic Tec plate heat exchanger is produced?

Polypropylene foam insulation for those heating devices is typically produced through a process called extrusion. In this process, polypropylene pellets are melted and mixed with a blowing agent, then forced through a die to create foam. The foam is then cooled and cut into sheets or other shapes as needed. Additional treatments may be applied to the foam to improve its properties, such as flame retardants or UV stabilizers. The resulting polypropylene foam insulation is lightweight, flexible, and provides excellent thermal insulation properties. The main cost of creasting an insulation is not a raw material itself but the costs of tooling for specific shapes - and then the heating fuel (as it require to heat up the machines up to the specific temperatures). Moreover as the tooling for a thermal insulation is a very expensive element - it's economically worth to invest it only if there's a demand for big quantities of a specific shape.

IZ-Ba-27/32-50

205 Items

New

No reviews

You might also like