B-Line Pool Titanium Exchangers

Pool Titanium Heat Exchanger NORDIC B360-Ti 110KW (360kBTU/H)

B-Line Pool Titanium Exchangers

Titanium heat exchanger for pools with saltwater or with added salt B300-Ti

The B300-Ti heat exchanger in the titanium version is primarily used for heating pools with saltwater, or potentially for other aggressive fluids.

☑️ Fast availability of titanium heat exchangers B300-Ti

✅ Fast and free delivery in IT, FR, ES, DE, PL, SI, AT, DK, NL, BE, CZ, LV, EE, LT

Titanium heat exchanger - for pool heating. Heat exchanger with a rated power of 90 kW.

* Rated Power - 90 kW (300 kBTU/h)

The actual power varies if the delta is lower.

An important aspect is the use of a glycol solution: in this case, efficiency will decrease by 8-15% if glycol is used on one side, and up to 30% if used on both sides.

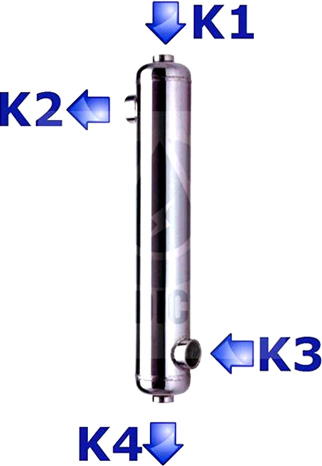

Connections

Nominal flow rate

Safe operating temperature - < 207.0 °C

Connecting the titanium heat exchanger B300-Ti to the system requires careful planning and the use of appropriate components to ensure optimal performance and a long lifespan of the heat exchanger. Below are some suggestions.

__________

You might also like