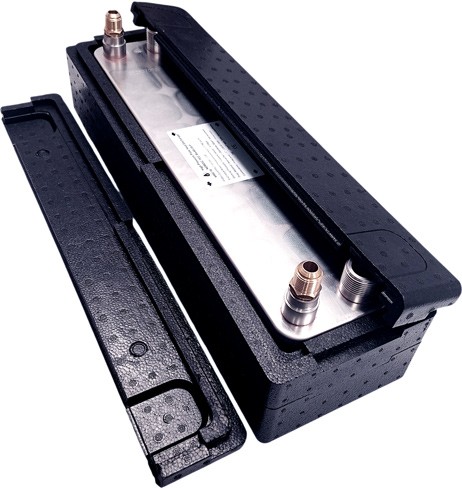

Adapters-Solder Nippels - Pipe 7/8" to SAE Thread

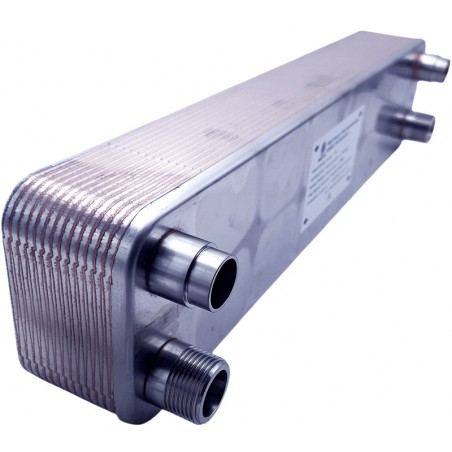

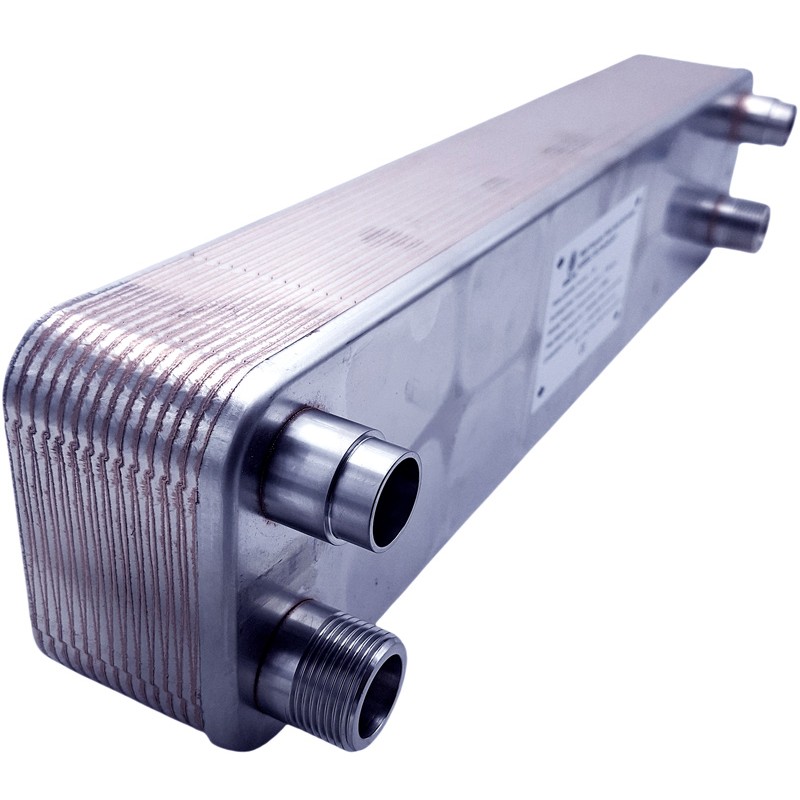

Freon Heat Exchanger Nordic Tec Ba-68-26-F 1,77m²

Refrigerant-Gas Heat Exchanger - Refrigerant Condenser - 26 Plates

Refrigerant-Gas Heat Exchanger - Suitable for Freon or Gas Media (Including High-Pressure)

Characteristics of the refrigerant exchange channels:

- Channel 1 - designed for freon/gas/refrigerant - equipped with solder connections - i.e., tube with a size of ϕ 22 - 7/8".

- Channel 2 - designed for liquid (water/glycol solution).

Number of stainless steel layers: 26 plates

- Heat exchange surface: 1,77 m²

- Heat pump/heat unit/air conditioner capacity: 13-18 kW

- Operating pressure on the gas side: max. 45 bar The resistance of refrigerant exchangers to pressures up to 45 bar is a primary feature that sets them apart from conventional liquid-liquid exchangers.

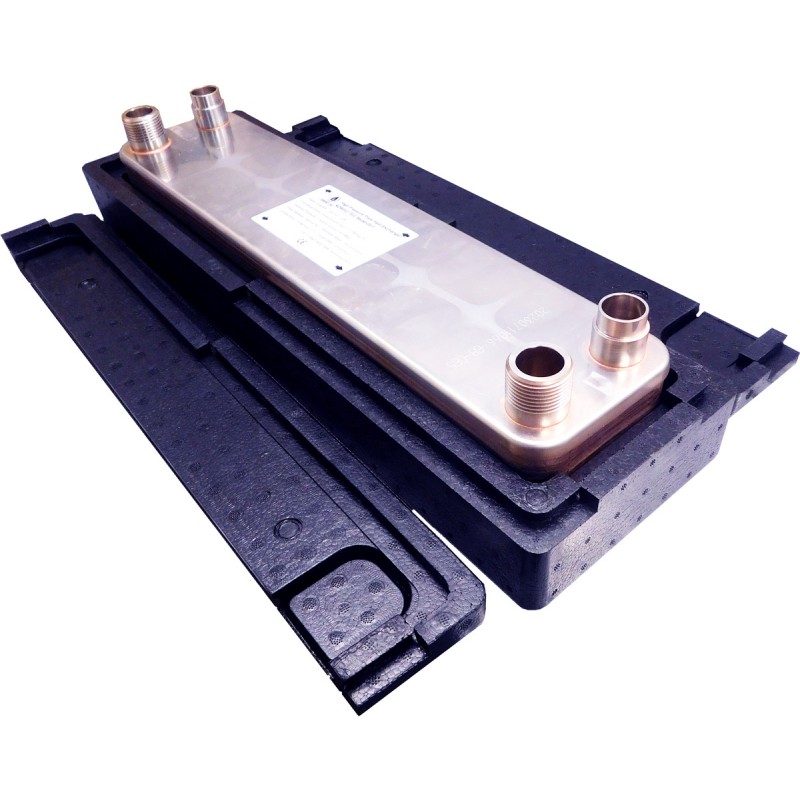

Thermal insulation is an optional accessory for the exchanger; you can purchase it with or without insulation. The selection menu is located below, just above the price.

☑️ We deliver to almost every European destination or country

✅ Free delivery in: FR, IT, ES, DE, PL, SI, AT, DK, NL, BE, CZ, LV, EE, LT

Reference: EU-Ba-68-26-F

Condition New

Freon heat exchanger - 13 kW - 18 kW condenser or evaporator

Plate Heat Exchanger for Refrigerants in Heat Pumps (Serving as an Evaporator or Condenser) or Refrigeration Units and Air Conditioners.

Plate Heat Exchanger for Heat Pumps or Air Conditioners, Suitable for Larger Units in the Range of 13 kW - 18 kW

Accessories visible on the photo are optional and are not the part of the basic set. You can find them in our shop ✅.

☑️✅ Check: The Solder Adapter for Refrigerant Exchanger's Tubes to SAE Thread

Technical details:

- Stainless steel 316L, welded brazed with Cu

- Heating capacity for heat pump / air conditioner / refrigeration unit: 13-18 kW

Parameter:

R410a Freon side; Tcon = 40ºC,

Liquid side: Water; T-IN= 32ºC; T-OUT = 37 ºC

- Refrigerant/gas connections: ϕ22 - 7/8" for brazing

- Liquid medium connections: 1" - DN 25

- Operating pressure: up to 45 bar

- Pressure test before commissioning: > 60 bar

- Flow rate: 22 m3/h

- Connection method: counterflow principle

Heat exchange surface area of the Ba-68-26-F heat exchanger - 1.768 m²

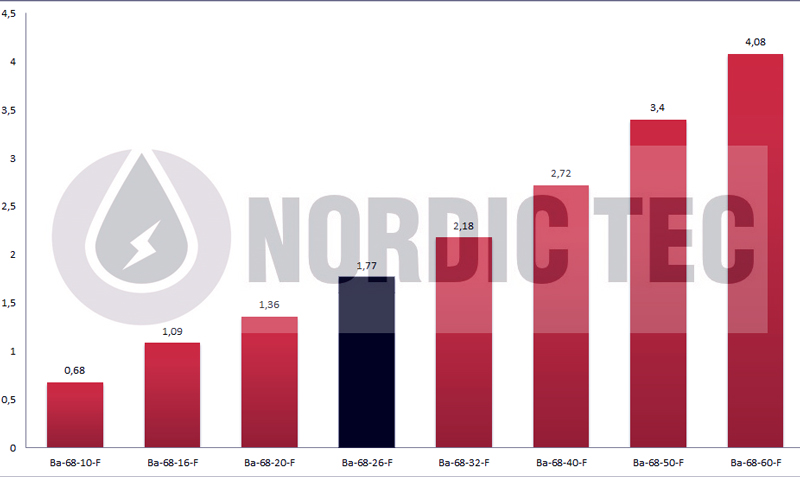

The Ba-68-26 refrigerant heat exchanger is one of the Nordic Tec gas or refrigerant exchangers from the Ba-68 series, positioned in the middle of the series in terms of its performance and heat exchange surface area. With 26 plates - and a surface area of steel plates amounting to 1,768 m², it provides excellent support for heat pumps or units operating with refrigerants like R410a, R32, R290, R404, or similar media. It is well-suited for devices with a nominal capacity ranging between 13 kW and 18 kW. Within the Ba-68-F series, you will also find larger refrigerant-water exchangers with surface areas exceeding 3-4 square meters.

The Ba-68-26-F gas heat exchanger, like any exchanger in this series, can be ordered in the basic/default version (a bare unit without thermal insulation) or with thermal insulation. An insulated heat exchanger is particularly beneficial for heating applications, as the insulation enhances its efficiency and minimizes heat loss to the surroundings.

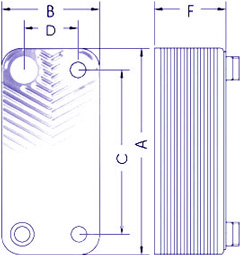

Dimensions:

(A) - 526 mm

(B) - 119 mm

(F) - 70 mm

(C) - 470 mm

(D) - 63 mm

EU-Ba-68-26-F

32 Items

New

No reviews

You might also like