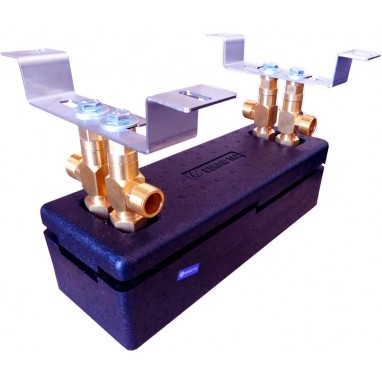

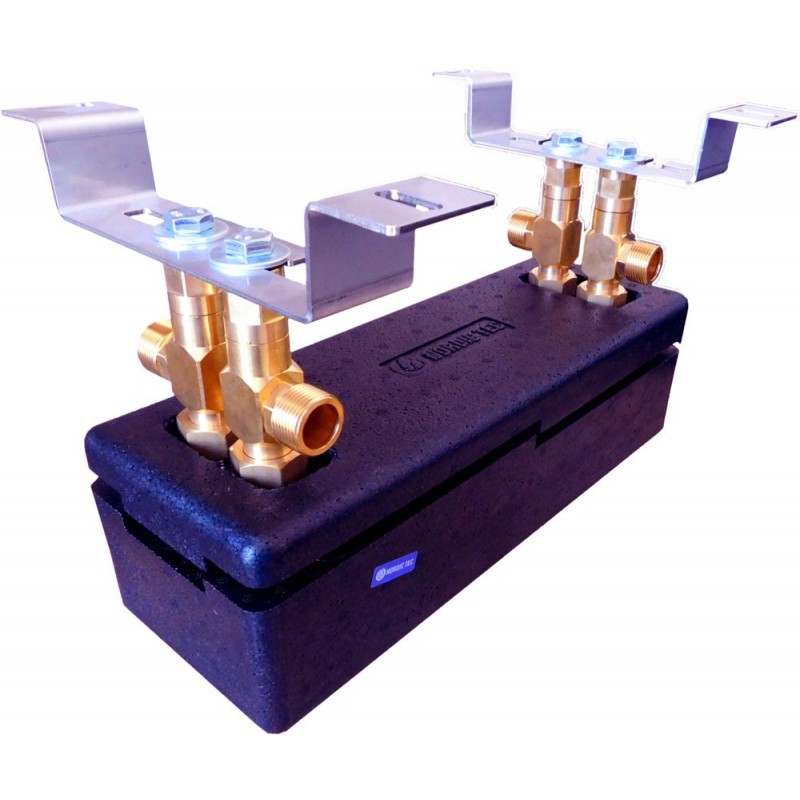

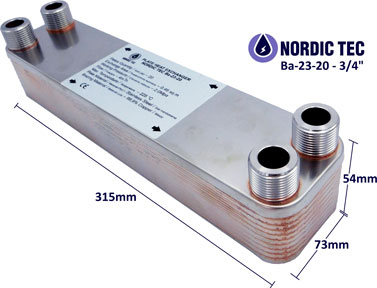

Plate Heat Exchanger NORDIC Ba-23-20 3/4" 90kW

Plate Heat Exchanger NORDIC TEC Ba-23-20

- Plate Q'ty: 20

- Connections: 3/4" BSP

- Heat Exchange Area: 0.460m²

☑️ Fast delivery to most European destinations: just in few days.

✅ FREE shipment in the following directions:

FR, IT, ES, SI, AT, DE, DK, NL, BE, CZ, PL, LV, EE, LT

20-plate Heat Exchanger - Nordic Tec Ba-23-20 - 4x 3/4", 20 plates

In practice, 20-plate heat exchanger Ba-23-20 works best for use with boilers or other heating devices operating at temperatures around 50-60 degrees Celsius with a power output of approximately 15-18 kW. This heat exchanger is not recommended for connecting heat pumps as they require larger heating exchange surfaces.

Details - 20 plate heat exchanger

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 3/4", BSP

- Working Pressure - <20 bar

- Test Pressure - 40 bar

- Max. temperature +230°C

- Flowrate - 4 m³/h

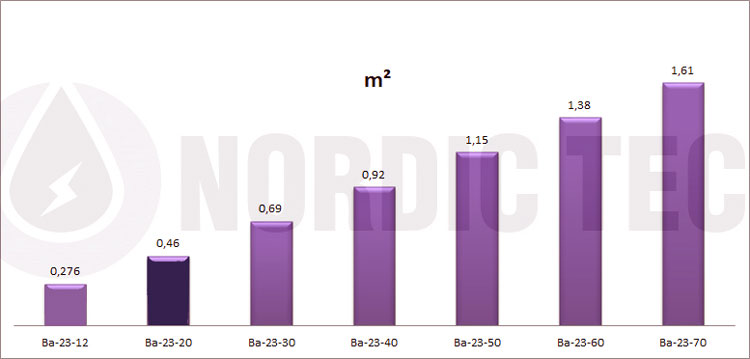

Heat Exchange Surface of a 20-plate heat exchanger Ba-23-20 - 0.460 m²

The most common application of a 20-plate heat exchanger Ba-23-20

- installation with a fireplace with a water jacket with a capacity of approx. 15kW

- support for condensing gas boilers up to 15-18 kW

- work with heating boilers for pellets, biomass, wood or other fuel with max. 15-18kW

- DHW installations with an additional tank (connecting extra heat source)

- solar panels (traditional, glycol) - heat exchanger for a solar collector for heating DHW

- home brewing, as a cooler of beer wort - if you want to check our homebrewing plate chillers check this out

- industrial refrigeration

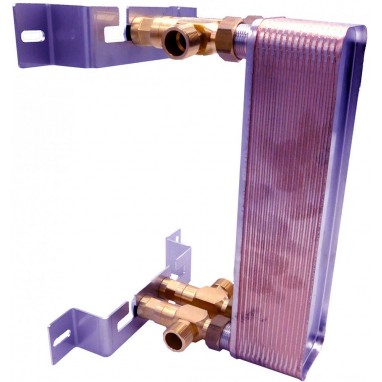

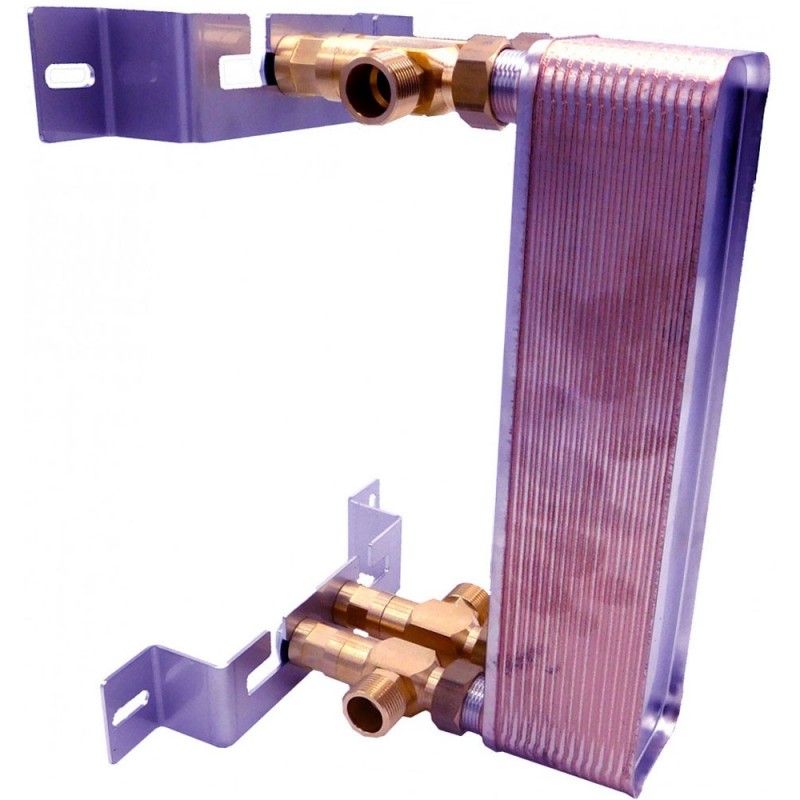

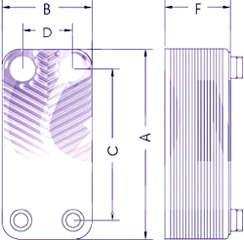

Dimensions - 20-plate heat exchanger Ba-23-20

(A) - 315 mm

(B) - 73 mm

(F) - 54 mm

(C) - 278 mm

(D) - 40 mm

How do brazed plate heat exchangers Ba-23-20 work?

A brazed plate heat exchanger is a device which consists of steel plates - spaces between them are little channels for water. Every plate heat exchanger (or just PHE) has 2 circuits, for hot and for cold fluid. Thus - heating medium and cool medium going througout the device exchange their temperatures. This device uses the simpe physical theory of heat transfer which says that between 2 fluids "Heat" is always transferred from a hot medium to a cold one. The task for a PHE is to use this procesuss to heat up the central heating installation of a house. That is the most popular application but not the only one.

Browse our catalogue and contact us if you need any help! ![]()

Connecting an open and closed system (sealed system) with a heat exchanger Ba-23-20

This is a classic, most widespread use of a plate exchanger. To briefly explain the issue for laymen, central heating systems can be closed (they are sealed, they are constantly circulated in them, although of course they have protection that allows you to reduce pressure in the system so that it does not lead to damage). Closed or sealed systems have a certain advantage over the open - among others they are healthier for heating devices (e.g. for boilers or heat pumps), and thanks to the fact that we do not pour water to them regularly have a less tendency to generate limescale, the main enemy of the efficient heating system. Most modern devices, e.g. gas or condensing boilers, should work in a sealed system. However, older devices, e.g. coal boilers, wood boilers or fireplaces with a water jacket are inert enough that they are recommended to be installed in the open system. It is just more secure, from the point of view of high pressure strength, generated by this type of heating (they do not have such good control on the temperature of the system, such as gas boilers that can turn off automatically at any time). So what can we do, which system to decide if we want to have 2 heat sources in our home - including one predestined to the sealed one, and the other to the open one? E.g. a heat pump + fireplace or gas heating with a fireplace? Or maybe heating by the Electric furnace with a coal boiler left just in case?

The best way to combine both systems to exchange heat without mixing the media - is a heat exchanger. However, the condition of operation of the system that connects the sealed with an open system is the correct selection. The exchanger must have the sufficient surface - otherwise the system will not work.

You might also like