Plate Heat Exchanger NORDIC Ba-16-60 1" 200kW

Heat Exchanger for HVAC Installations NORDIC TEC Ba-16-60

Brazed 60-plate heat exchanger – most commonly used as a heat exchanger for central heating (CH), specifically for separating closed and open systems. In this application, the 60-plate exchanger can work with central heating boilers and fireplaces. It has 1-inch connections.

- Plate Q'ty: 60 pcs.

- Connections: 1" BSP

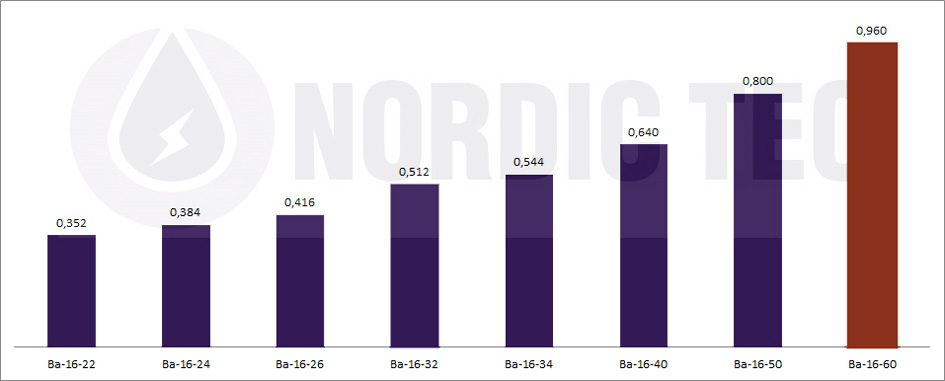

- Heat Exchange Area: 0.960m²

☑️ Free help with heat exchanger's sizing

✅ Free delivery in the following countries:

IT, ES, FR, AT, DE, NL, PL, DK, CZ, BE, LT, LV, EE, SI

Reference: NT Ba-16-60

Condition New

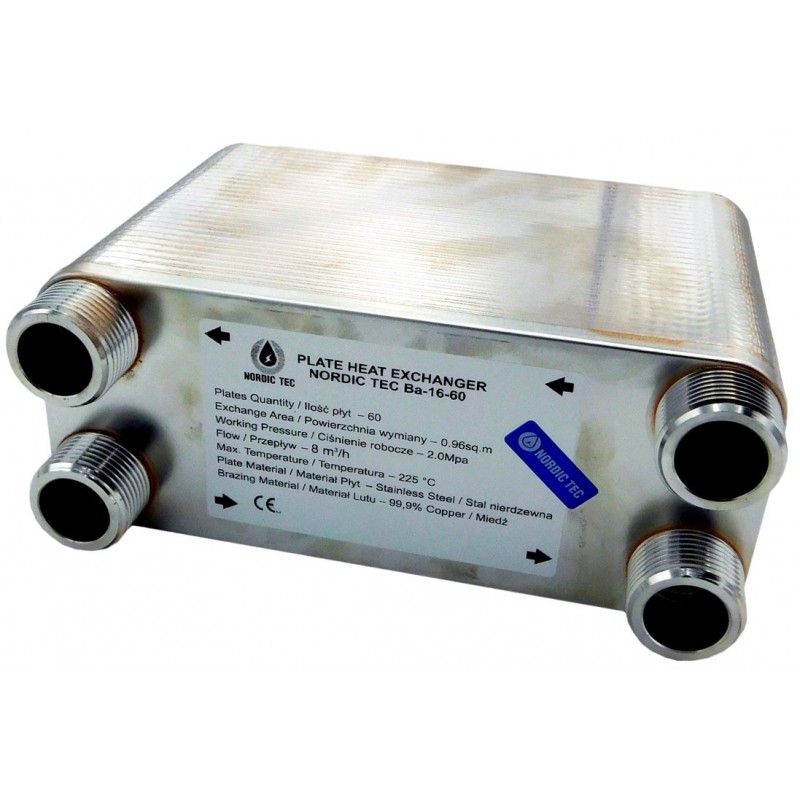

Heat Exchanger Nordic Tec Ba-16-60 - 4x 1", 60 plates

Nordic Tec Ba-16-60 1-inch heat exchanger

Technical details - Heat Exchanger Nordic Tec Ba-16-60:

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 1", BSP

- Working Pressure - <20 bar

- Test Pressure - 40 bar

- Max. temperature +230°C

- Flowrate - 8 m³/h

- Heat Exchange Surface - 0.960 m²

The heat exchange surface – that is, the surface area of the plates in the 60-plate exchanger from this offer – is 0.96 square meters, making it one of the larger models in the Ba-16 series.

In 2024, the company Nordic Tec added the Ba-16-70 heat exchanger with 70 plates to its regular catalog, featuring a total surface area of 1.12 m².

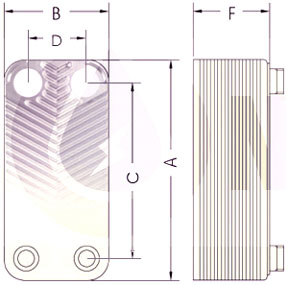

Dimensions:

(A) - 220 mm

(B) - 90 mm

(F) - 144 mm

(C) - 180 mm

(D) - 52 mm

More information about 60-plate Heat Exchanger Ba-16-60:

The Ba-16-60 plate heat exchanger by Nordic Tec is an efficient and reliable solution for transferring heat between two fluids. With 60 plates and a compact design, it offers a large heat transfer area (0.96 m²) while requiring minimal space in our boiler-room. This model is suitable for a variety of applications, like hydronic heating, DHW - domestic hot water, and industrial cooling/heating processes. The Ba-16-60 is constructed from high-quality stainless steel, ensuring durability and resistance to corrosion. Almost no maintenance is required. This plate heat exchanger is an ideal choice for those people who look for a cost-effective solution.

With the plate area as mentionned, almost 1 square meter - this unit can easily operate a central heating system in a detached house of 250-400m² (depending on a building condition). It can as well easily cooperate with boilers in a row of 30-35 kW. It's enough for long years of work, even if we include the natural process of PHE aging.

- ☑️ BLOG: Connecting a gas boiler to an open system with a plate heat exchanger

- ✅ BLOG: Why a plate heat exchanger shouldn't be used with pre-treated water?

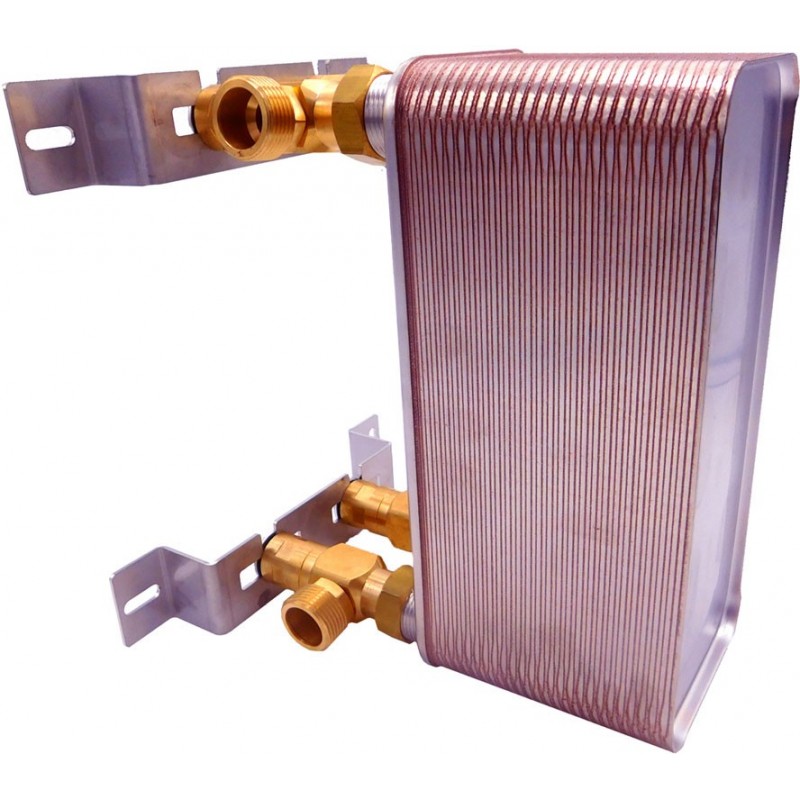

Recommended accessories for the heat exchanger – optional choice:

1-inch ball shut-off valve with thermometer for installation with a plate heat exchanger

For any device such as a plate heat exchanger, it is worth considering the installation of valves to block the water supply and remove the device from the system in case of any malfunction. This also applies to devices that rarely fail, such as heat exchangers, because every device may require servicing. In the case of heat exchangers, installing valves allows us to disconnect the device and perform necessary cleaning without draining the entire system of water. Theoretically, a plate heat exchanger should be cleaned once every 12–18 months.

Thermometers are recommended to be installed on the inlet and outlet of the heat exchanger to monitor the efficiency of heat exchange. They allow diagnosing potential problems and responding, for example, by cleaning the heat exchanger or adjusting pump flows in case of a temperature drop across the exchanger.

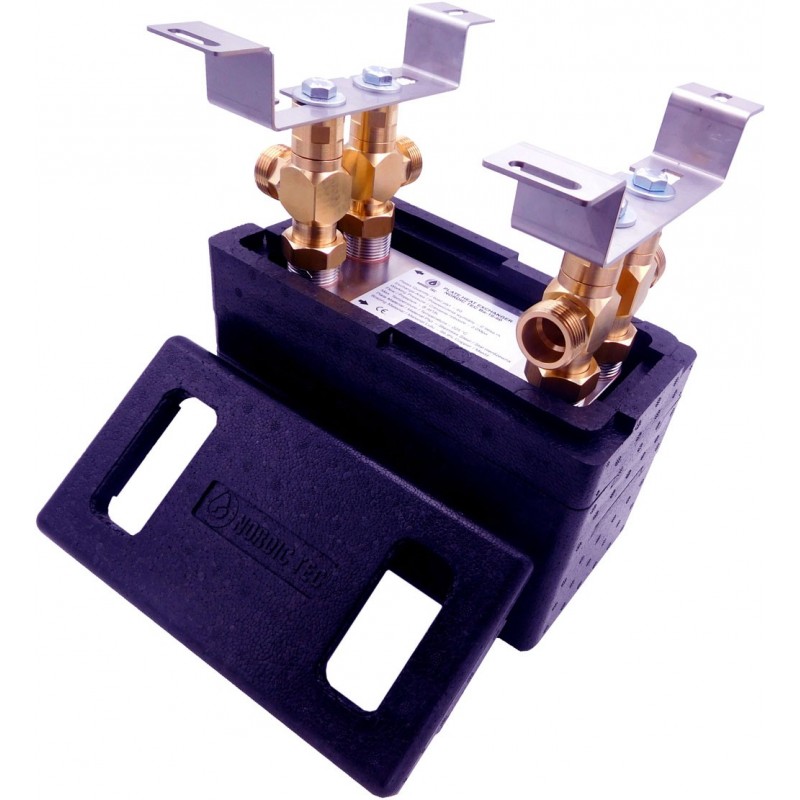

Thermal insulation (or casing) for the 60-plate heat exchanger

The insulation for the heat exchanger, made of black polypropylene foam, is designed to reduce heat losses, i.e., the escape of thermal energy from the heat exchanger to the outside. This heat loss must be compensated for by producing additional thermal energy from the boiler (or heat pump). Therefore, it should be minimized to avoid unnecessary costs. Heat losses caused by an uninsulated exchanger typically range from a few to several percent of the thermal energy flowing through the exchanger, depending on various factors such as supply temperature, room temperature, and mainly the external surface area of the plate heat exchanger.

For obvious reasons, insulation is not installed on heat exchangers used in refrigeration systems.

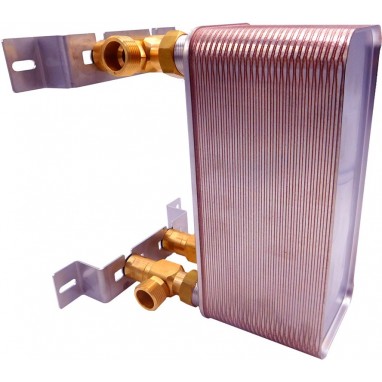

Mounting kit for the 1-inch heat exchanger

The kit contains all suspension components for 1-inch plate heat exchangers, in this case, compatible with Ba-16-60 models – sized 1" / DN25. The ready-made bracket kit offers significant time savings for installers, as it eliminates the need to search for each individual component (which would be difficult anyway). It provides great convenience in arranging the heat exchanger connections because it includes rotary fittings.

An invaluable advantage is that the heat exchanger is securely mounted for many years. Thanks to the bracket, no micro-turbulence generated by the circulation pumps will cause any leakage in the heat exchanger connections.

NT Ba-16-60

163 Items

New

No reviews

You might also like