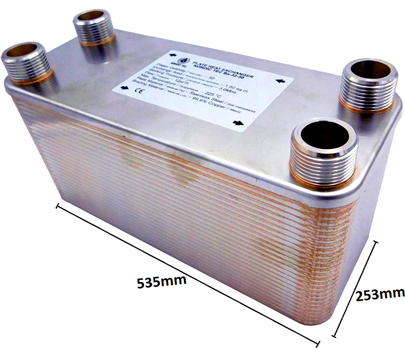

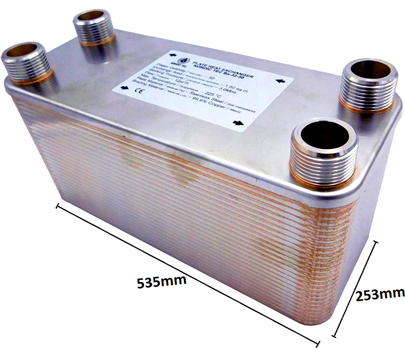

Plate Heat Exchanger with Large Heat Transfer Area Nordic Tec Ba-115-120 - 4x 2", 120 plates

DN50 brazed steel heat exchanger with copper, 2" connections, 120 plates

Technical details - Plate Heat Exchanger Nordic Tec Ba-115-120

|

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 2", BSP

- Working Pressure - up to 30 bar

- Test Pressure - 45-60 bar

- Max. temperature +230°C

- Flowrate - 45 m³/h

|

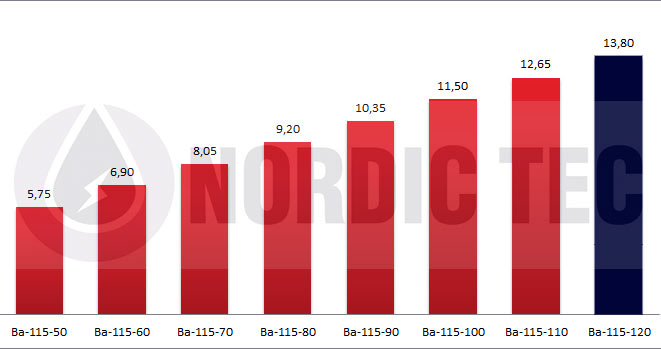

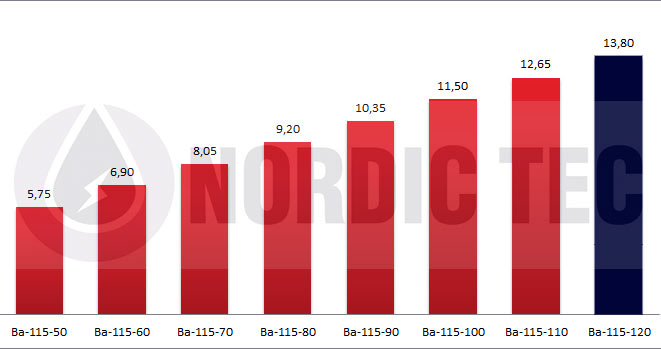

Heat Transfer Area of a 120-plate heat exchanger - 13.800 m²

The 120-plate heat exchanger is certainly an industrial-sized model designed for demanding applications, such as heating multi-family buildings or commercial facilities. It can also handle systems that require very high heat transfer efficiency, such as low-temperature heat sources, heat pumps, and more. Additionally, it can be used to connect large buildings to a district heating network.

The plate surface area of this model is approximately 14 m². If you need an even larger plate surface, you can also consider slightly larger models, such as the 130-plate version (Ba-115-130) or the 140-plate version (Ba-115-140).

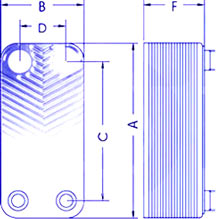

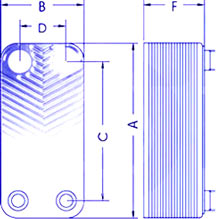

Dimensions - 120-plate heat exchanger Ba-115-120

A - 535 mm

B - 253 mm

C - 456 mm

D - 174 mm

F - 304 mm

The Nordic Tec plate heat exchanger with 120 plates operates in counterflow | Ba-115-120 2"

When installing the above-mentioned heat exchanger – whether in a heating or cooling system – it is important to keep in mind that this is a classic counterflow plate heat exchanger, like all Nordic Tec plate heat exchangers. This means that you can freely choose either of the two channels as the inlet, but regardless of your choice, the fluid in the other channel must flow in the opposite direction. In other words, the fluids in the two channels of the plate heat exchanger must flow in opposite directions.

Ignoring this counterflow rule is still a common mistake during the installation of plate heat exchangers and mainly results in a reduction in heat transfer efficiency. It is estimated that a plate heat exchanger connected in so-called parallel flow (both fluids flowing in the same direction) loses approximately 30–40% of its efficiency.

Plate heat exchangers specifically designed for parallel flow must be installed in this configuration, and the manufacturer should provide specific guidance accordingly.