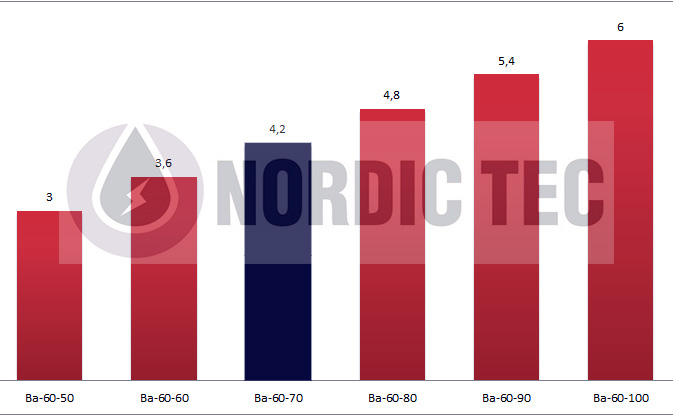

Plate Heat Exchanger NORDIC Ba-60-70 1 1/2" 770kW

Plate Heat Exchanger NORDIC TEC Ba-60-70 1 1/2"

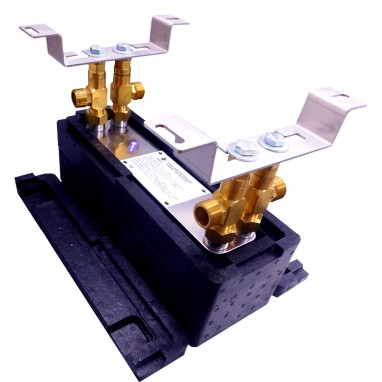

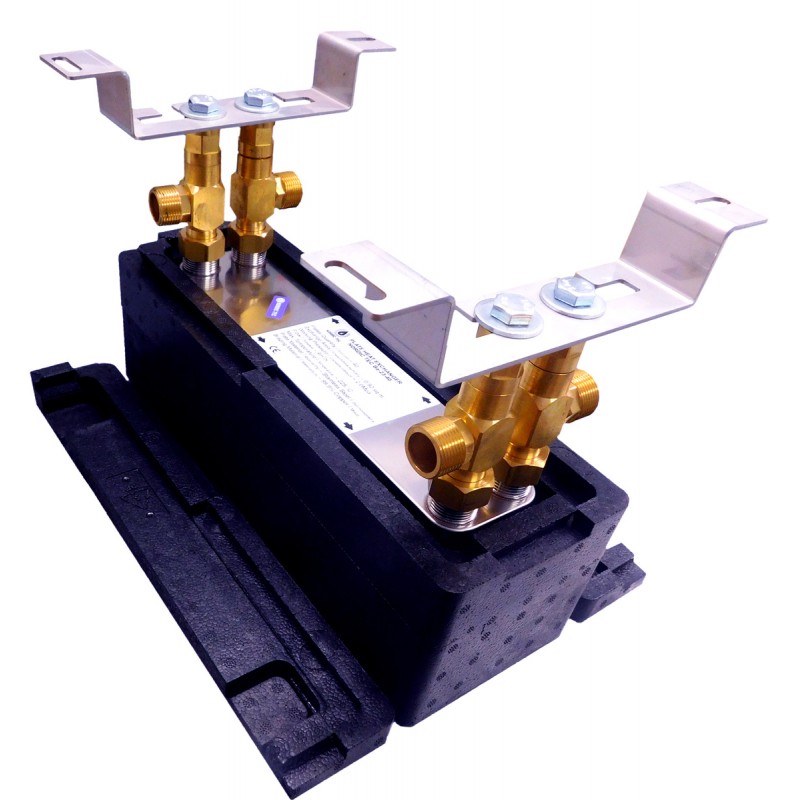

Heat exchanger with 70 plates and large diameter connections, i.e., 1 1/2". Optionally available with insulation and wall bracket for 1 1/2" connections.

- Plate Q'ty: 70 pcs.

- Connections: 1 1/2" BSP

- Heat Exchange Area: 4.200m²

☑️ Quick delivery of our heat exchangers in most European countries

✅ Free shipment in the following countries: DE, PL, FR, ES, IT, AT, NL, BE, DK, CZ, LT, LV, SI, EE

Reference: NT Ba-60-70 1 1/2"

Condition New

Heat Exchanger for heat pump connecting - Nordic Tec Ba-60-70

Heat Pump Water/Glycol Heat Exchanger 4x 1 1/2", 70 plates

Technical details:

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 6/4", BSP

- Operating pressure - up to 30 bar - the exchanger is designed for use with liquids (not for gas media)

Test pressure - 45-60 bar - the pressure at which the unit is tested before being approved for sale - Max. temperature +230°C

- Flowrate - 22 m³/h

Heat Exchange Surface for PHE Ba-60-70 - 4.20 m²

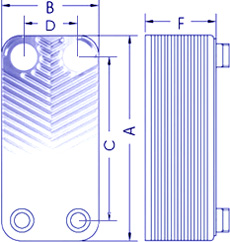

Dimensions:

(A) - 526 mm

(B) - 124 mm

(F) - 175 mm

(C) - 478 mm

(D) - 73 mm

__

The heat exchanger for a monoblock heat pump with a capacity of 30 kW or a split heat pump with a capacity of 32 kW

NT Ba-60-70 1 1/2"

0 Items

New

No reviews

You might also like