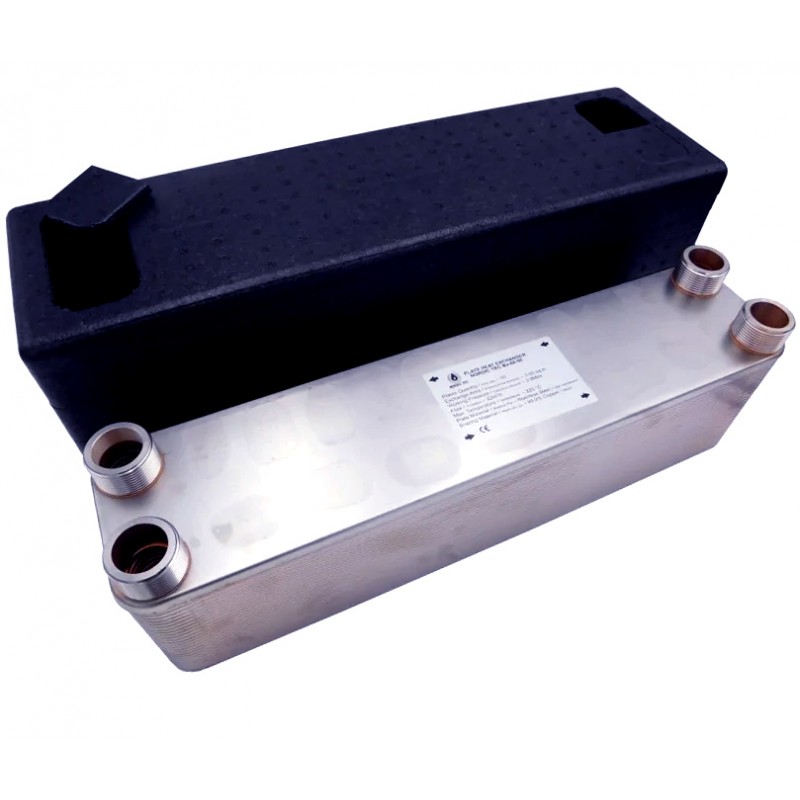

Plate Heat Exchanger NORDIC Ba-60-60 1 1/4" 660kW

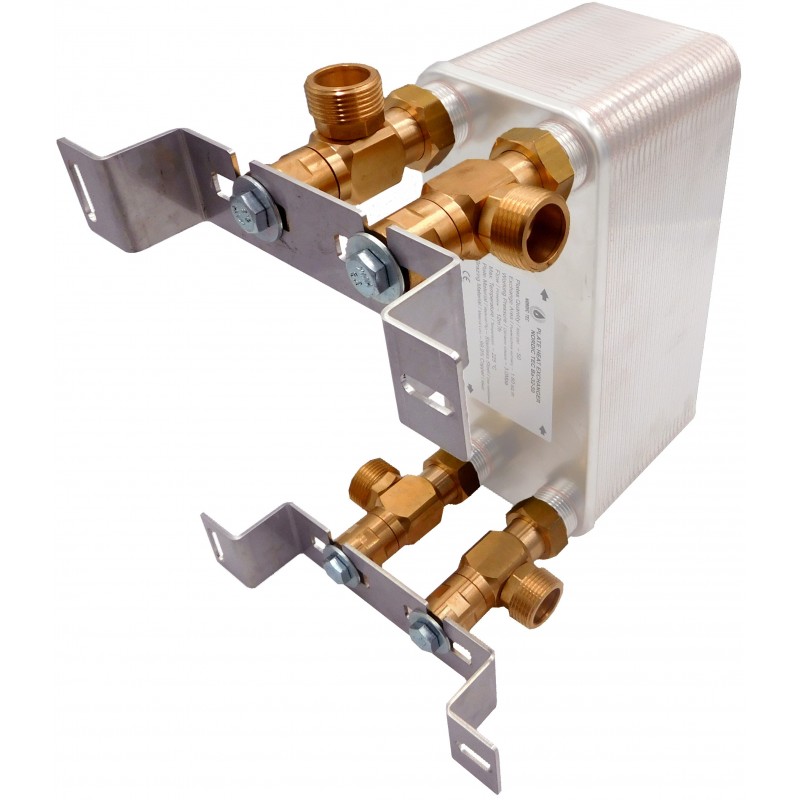

Plate Heat Exchanger NORDIC Tec Ba-60-60 5/4"

- Plate Q'ty: 60 pcs.

- Connections: 1 1/4" BSP

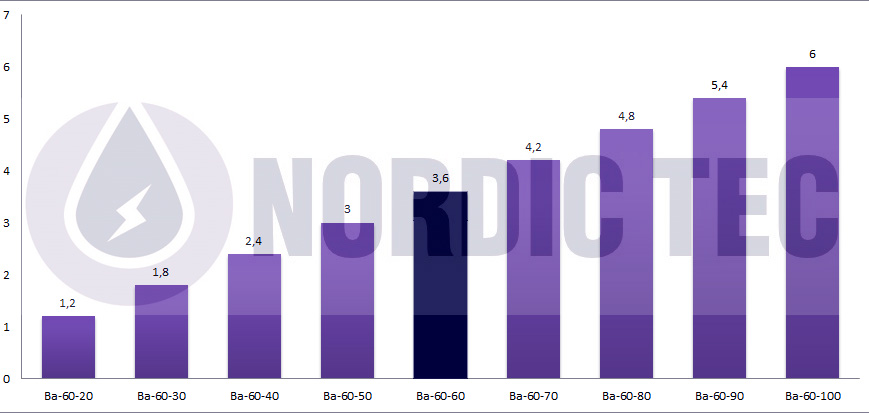

- Heat Exchange Area: 3.600m²

60-plate heat exchanger for heat pumps or boilers. It can work with both water and glycol. It has a large plate surface and a substantial connection diameter of 1 1/4". It is most commonly chosen as a heat exchanger for separating monoblock heat pumps (glycol-filled systems) from the rest of the central heating or domestic hot water system.

☑️ Fast accessibility & quick delivery of our heat exchangers in most European countries

✅ Free shipment in the following countries: DE, PL, FR, ES, IT, AT, NL, BE, DK, CZ, LT, LV, SI, EE

Reference: NT Ba-60-60

Condition New

Technical details - Nordic Tec Ba-60-60 Plate Heat Exchanger (PHE)

- Stainless Steel S316L, brazed with 99,9% Cu

- Heat Exchanger's Connections: 4x 5/4", BSP

- Working Pressure - <30 bar (Liquid-Liquid PHE)

- Test Pressure - 45-60 bar

- Max. temperature +230°C

- Nominal Flowrate - 22 m³/h

Heat Exchange Surface - Plate Heat Exchanger Ba-60-60 - 3.600 m²

What is the Ba-60-60 Nordic Tec plate heat exchanger used for?

- Plate heat exchanger with 60 plates is used in central heating installations that require a PHE, i.e., to separate a closed circuit from an open one, using various sources of heat."

- Connecting a plate heat exchanger to service a heat pump (monoblock or split) is necessary when there is a need to fill the heat pump circuit with water mixed with glycol. The recommended heat exchanger can generally handle heat pumps with a capacity of 11 to 24 kW, depending on whether it is a high-temperature or low-temperature system based on underfloor heating

- Servicing large condensing boilers in multi-family buildings, including cascaded combinations of gas boilers with a total power output of up to 120-150 kW

- Handling similar size boilers for eco-pea coal, coal, wood, pellets or biomass.

- Connecting buildings to the district heating network (DHN) in the case of multi-family housing through a plate heat exchanger

- Cooling - plate heat exchanger as an oil cooler in industrial applications

- Working with glycol systems in combination with solar panels of larger sizes

- Separating UFH - underfloor heating manifolds from open heating systems.

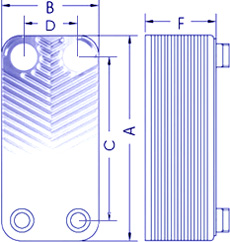

Dimensions:

(A) - 526 mm

(B) - 124 mm

(F) - 151 mm

(C) - 478 mm

(D) - 73 mm

__

In DOWNLOAD section you get the data sheet of the unit.

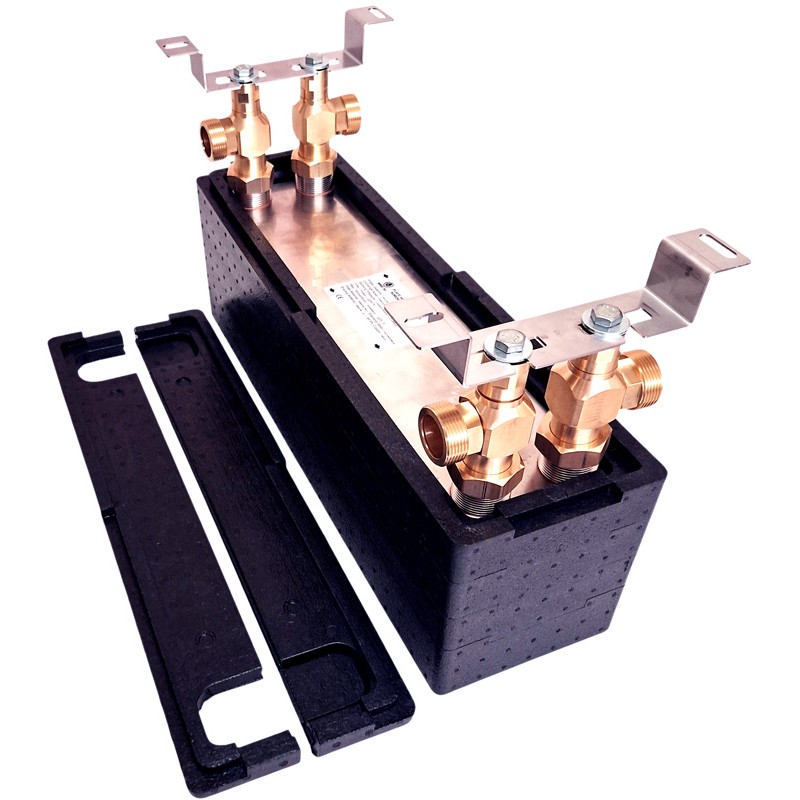

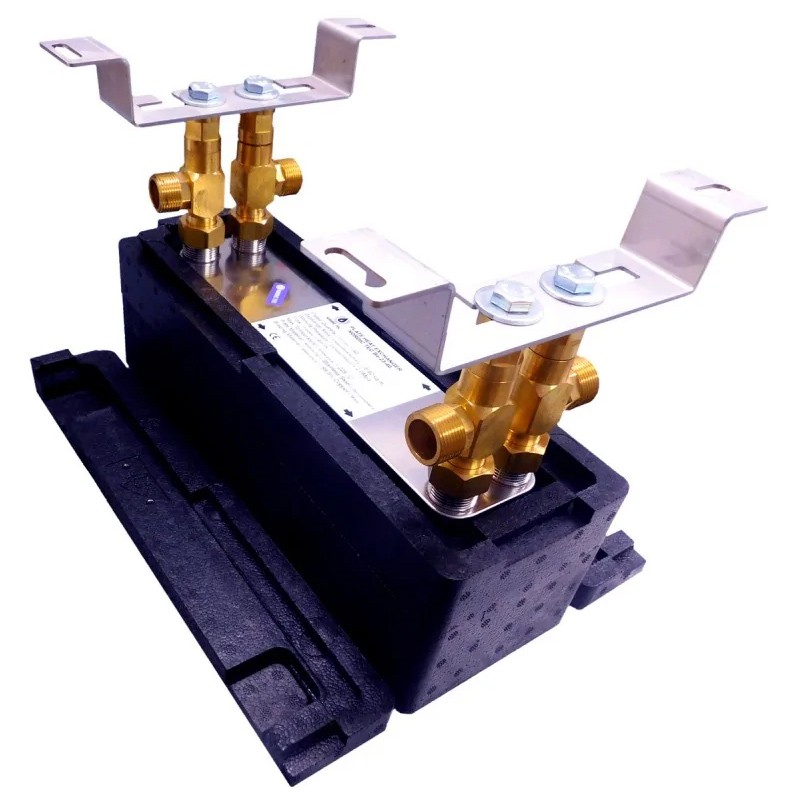

A full set of Ba-60-60 60-plate heat exchanger typically includes:

- This device can be purchased with accessories. To do so, you need to expand the "Heat Exchanger Accessories" menu and select the appropriate option. By default, the purchase option only includes the heat exchanger without any additional accessories

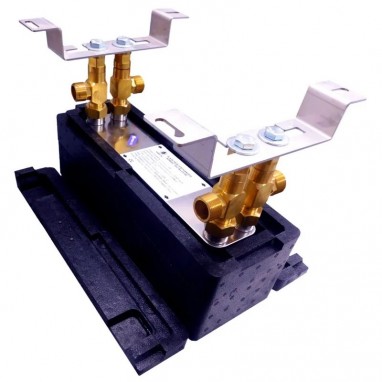

- Thermal insulation IZ-Ba-60-60 made of polypropylene foam to reduce heat losses on the heat exchanger

- PHE Mounting kit including a complete set of angled bolts, selected according to the size of the connections on the heat exchanger - that is 5/4 inch. This accessory is particularly recommended for the Ba-60-60 heat exchanger, as it weighs about 17.5 kg, which should be added to the weight of the media flowing through the heat exchanger. The bracket solves the problem of stable wall mounting.

NT Ba-60-60

1145 Items

New

No reviews

You might also like