Plate Heat Exchanger NORDIC Tec Ba-32-90 1" 500kW

Plate Heat Exchanger NORDIC TEC Ba-32-90 with 90 plates

Classic Brazed Plate Heat Exchanger 1" with 90 plates, working excellent way with Heat Pumps Monoblock (connecting glycol circuits of HP monobloc).

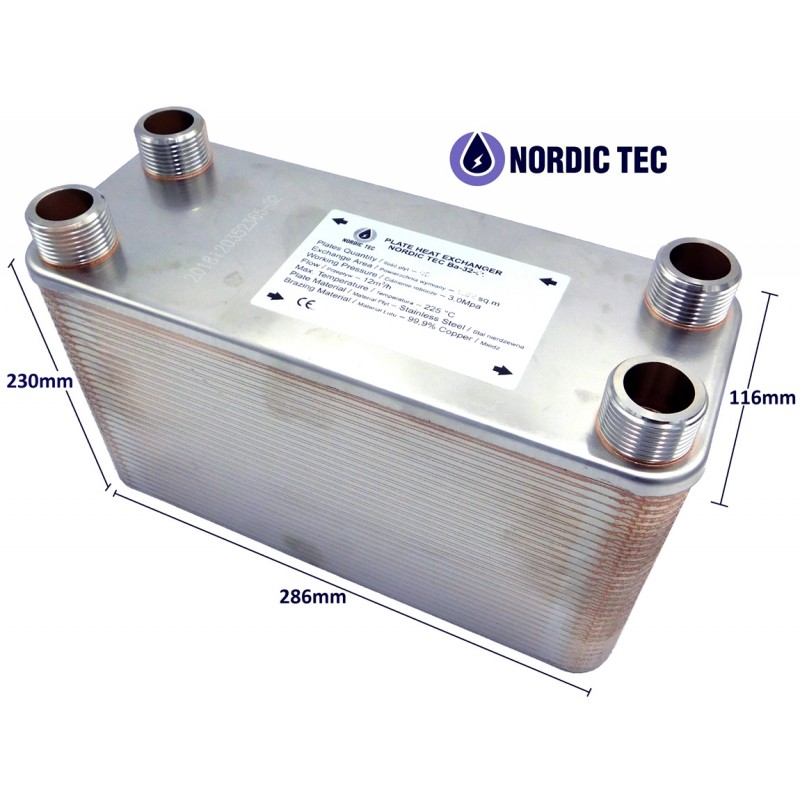

- Plate Q'ty: 90 pcs.

- Connections: 1" BSP

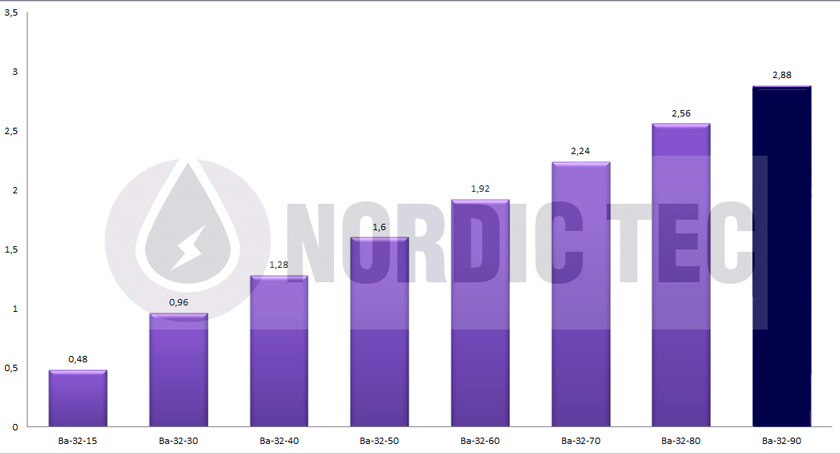

- Heat Exchange Area: 2.880m²

A heat exchanger with 90 plates per 1 inch - made of steel and copper-brazed, mainly designed for connecting monoblock heat pumps ( or other types if required ) as well as for large systems powered by heating boilers , regardless of the fuel type - for example gas condensing boilers, wood burners - only bigger units. This 90-plate device has a nominal capacity of 500 kW - suitable for high supply parameter requirements ( industrial service ).

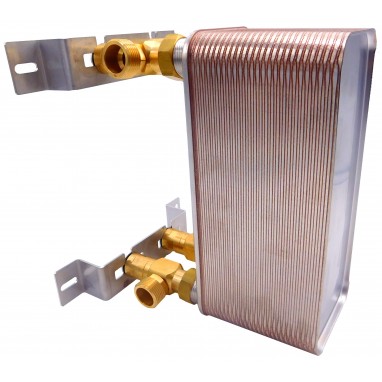

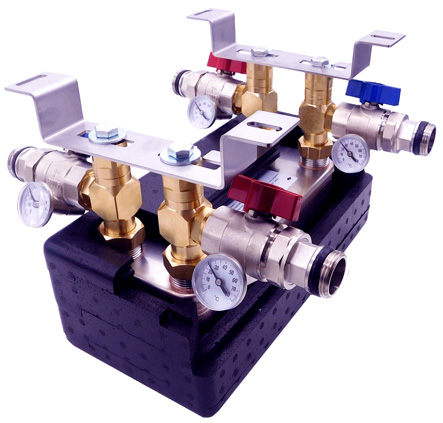

This plate heat exchanger (similarly to our other PHE) can be ordered standalone or optionally with insulation and mounting support - wall bracket with installation kit.

Reference: EU-NT Ba-32-90

Condition New

Nordic Tec Ba-32-90 - 4x 1", 90 plates

The brazed plate heat exchanger, Nordic Tec Ba-32-90, is designed to support monobloc heat pumps (glycol to water circuits) or another demanding heat transfer solutions.

The photo shows the Nordic Tec Ba-32-90 heat exchanger as a complete set

consisting of insulation, wall mounting set and ball valves incl. thermometer. The accessories are an option.

Technical details:

- Stainless Steel S316L (plate meaterial), Cu-Copper (brazzing material)

- Connections: 4x 1" / DN 25 , BSP, external threads

- Working Pressure - <30 bar, tested with 45-60 bar

Max. allowable pressure is 30 bar, so this is the heat exchanger for connecting monoblock glycol heat pump system with the central heating installations, but it is not the heat exchanger for gas media (like freon or other refrigerants - which tend to work over 30 bar pressure).

- Maximum temperature range +230°C

- Flowrate - 12 m³/h

Heat Exchange Surface / Heat Transfer Area of a Bs-32-90 PHE - 2.880 m²

Most common use of the 90-plate heat exchanger - not only heat pumps

- large surface heat exchanger for central heating installations - with coal boilers up to approx. 90 kW, eco-pea coal boilers up to approx. 90 - 100 kW

- plate heat exchanger for separating of the monoblock heat pump from the central heating system, using a monoblock with a capacity of up to 16 - 22kW

- separation of gas boilers and solid fuel boilers - in order to create a short circuit and balance pressures in the heating system (a function similar to a hydraulic separator - low loss header)

- cooperation with glycol heaters in bigger buildings and objects, e.g. in heating workshops or production halls, warehouses and similar

- refrigeration using thermal oil or similar media

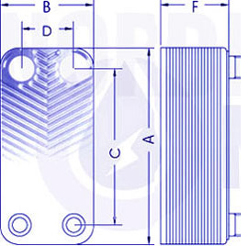

Dimensions:

(A) - 286 mm

(B) - 116 mm

(F) - 225 mm

(C) - 243 mm

(D) - 72 mm

___________________________________________________________________________

EU-NT Ba-32-90

161 Items

New

No reviews

You might also like