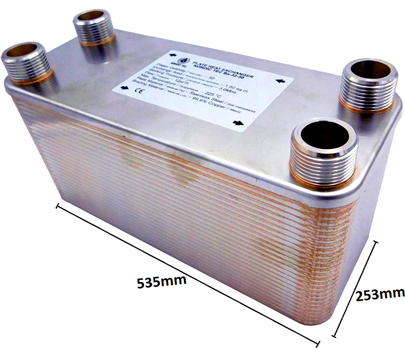

Plate Heat Exchanger NORDIC Ba-115-110 2" 3900kW

Plate Heat Exchanger with 110 Plates 2" NORDIC TEC Ba-115-110

- Plate Number: 110 pcs.

- Connections: 2", external thread

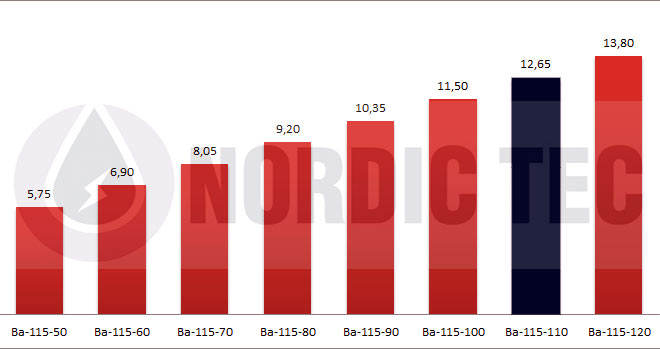

- Heat Exchange Area: 12.65 m²

Brazed plate heat exchanger – large model with 110 plates and a total surface area of 12.65 m² – for large industrial heating and cooling systems.

✅ This Heat Exchanger requires a pallet delivery - we offer the quick delivery of this plate heat exchanger in most European countries.

☑️ Fast availability of large Ba-115 heat exchangers and order processing in 1 working day

✅ Free delivery in: FR, IT, ES, DE, PL, SI, AT, DK, NL, BE, CZ, LV, EE, LT

Plate Heat Exchanger with Large Heat Transfer Area Nordic Tec Ba-115-110 - 4x 2", 110 plates

DN50 brazed steel heat exchanger with copper, 2" connections, 110 plates

Technical details - Plate Heat Exchanger Nordic Tec Ba-115-110

- Stainless Steel S316L, brazed with 99,9% Cu - Connections: 4x 2", BSP - Working Pressure - up to 30 bar - Test Pressure - 45-60 bar - Max. temperature +230°C - Flowrate - 45 m³/h |

Heat Transfer Area of a 110-plate heat exchanger - 12.650 m²

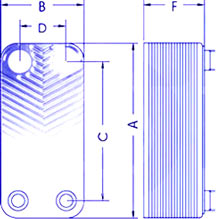

Dimensions - 110-plate heat exchanger

A - 535 mm

B - 253 mm

C - 456 mm

D - 174 mm

F - 279 mm

The Nordic Tec heat exchanger with 110 plates is designed for counter-flow operation

During the installation of the heat exchanger mentioned above, whether in a heating or cooling system, it's important to remember that this is a classic counter-flow heat exchanger, like all Nordic Tec plate heat exchangers. This means that for the supply connection, we can choose any channel, but regardless of this choice, the fluid in the second channel must flow in the opposite direction to the supply channel. In other words, the fluids in the two channels of the plate heat exchanger must flow in opposite directions.

Ignoring the counter-flow principle remains a common mistake in heat exchanger installations and primarily leads to reduced heat transfer capacity. It's estimated that a plate heat exchanger connected in so-called "parallel" mode (with both fluids flowing in the same direction) loses about 30-40% of its efficiency. Only heat exchangers specifically designed for parallel flow should be connected this way, and the manufacturer should clearly specify this.

You might also like