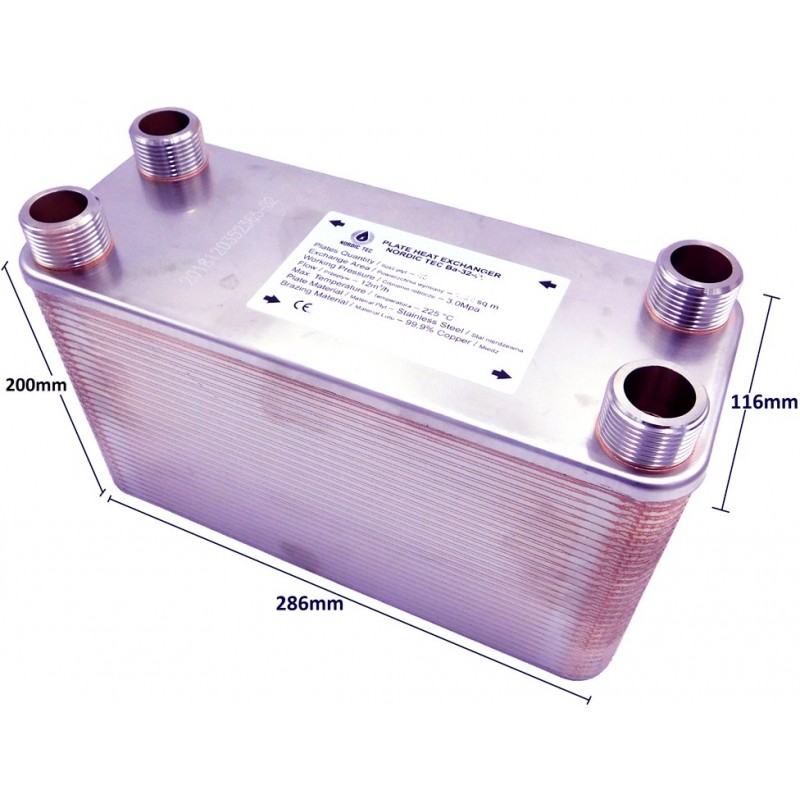

Plate Heat Exchanger NORDIC Ba-32-80 1" 450kW

Plate Heat Exchanger NORDIC TEC Ba-32-80 - mostly for monoblock heat pumps

Classic Brazed Plate Heat Exchanger, often used for Heat Pumps Monoblock (connecting glycol circuits of HP monobloc). having 80 steel plates.

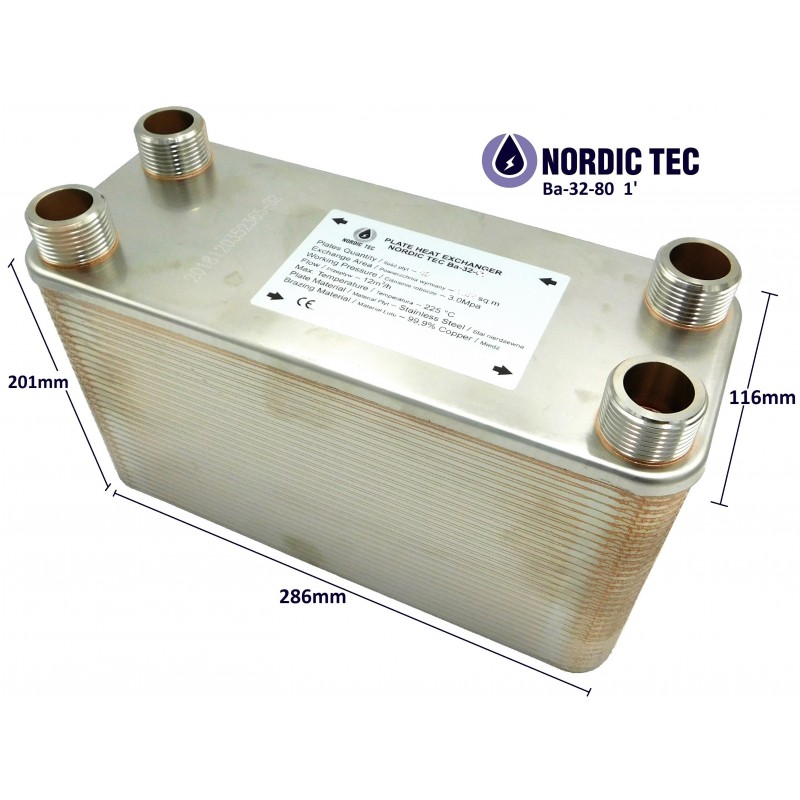

- Plate Q'ty: 80 pcs.

- Connections: 1" BSP

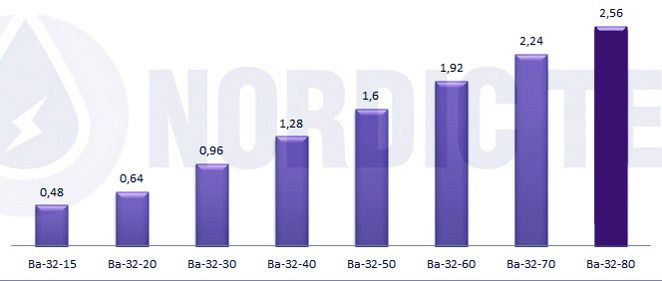

- Heat Exchange Area: 2.560m²

A heat exchanger with 80 plates per 1 inch - made of steel and copper-brazed, primarily designed for connecting monoblock heat pumps ( or other types if required ) as well as for large systems powered by heating boilers of even 80-90 kW, regardless of the fuel type. This 80-plate heat exchanger has a nominal capacity of 450 kW - suitable for high supply parameter requirements (industrial use). This plate heat exchanger can be ordered standalone or as an option with insulation and mounting support - wall bracket with installation kit.

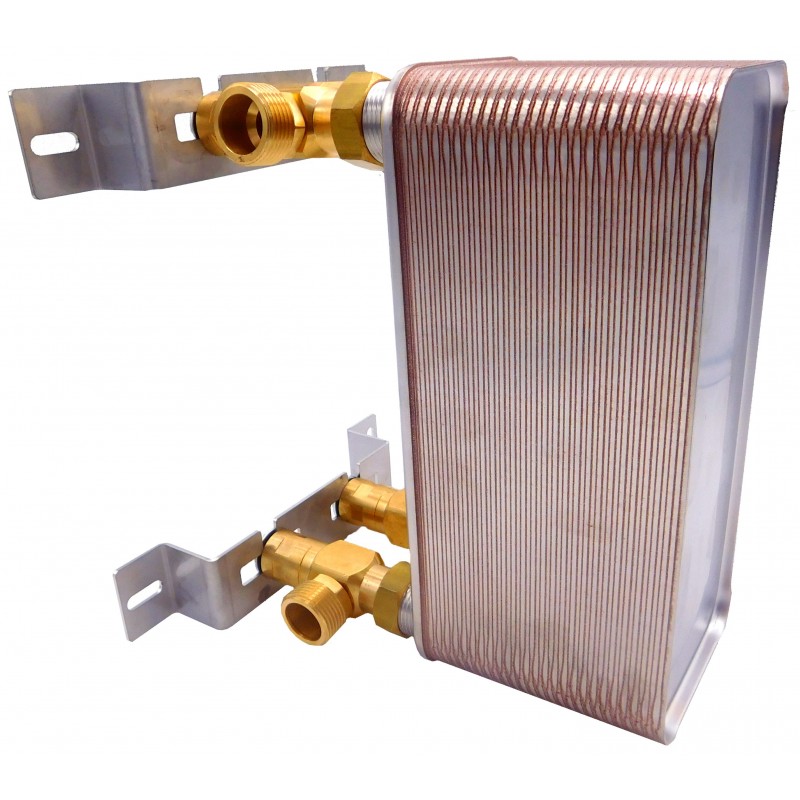

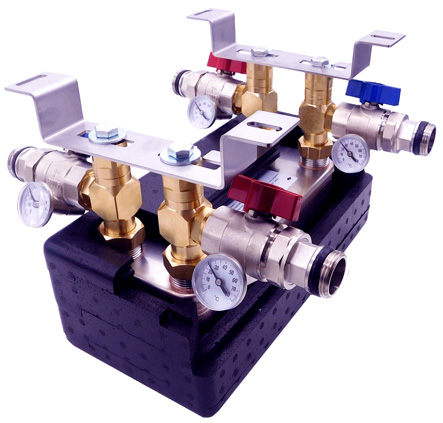

☑️ As an option - the possibility to purchase a Ba-32-80 BPHE with insulation and a mounting kit (wall-mounting with rotary fittings set)

✅ Quick availability & Free delivery in : FR, IT, ES, DE, PL, AT, SI, DK, NL, BE, CZ, LV, LT, EE

Reference: NT Ba-32-80

Condition New

Heat Exchanger for boilers or heat pumps - Nordic Tec Ba-32-80 - 4x 1", 80 plates

The brazed plate heat exchanger, Nordic Tec Ba-32-80, with a capacity of 450 kW (high parameters), is suitable for use with heat pumps (mostly monoblock water-glycol), large heating boilers, and also for cascade boiler systems.

The photo shows the Nordic Tec Ba-32-80 heat exchanger as a complete kit

consisting of insulation, wall mounting set and ball valves incl. thermometer. The accessories are optional.

Technical details:

- Stainless Steel S316L (plate meaterial), Cu-Copper (brazzing material)

- Nominal heating power - 450 kW

depending on the supply temperature. In practice, this translates to the heating power of boilers in the range of 80-90 kW, in some cases up to 100 kW. However, for heat pumps, it is more complicated because the selection depends on the supply temperature at which the heat pump is to operate. Nevertheless, there are monoblock heat pumps available from 9 kW to 18 kW (with glycol) or from 10 kW to 20 kW (water-water).

- Connections: 4x 1", BSP, external threads

- Working Pressure - <30 bar, tested with 45-60 bar

The heat exchanger should not operate with media requiring pressures higher than 30 bar, including R410a and R32, among others. The Ba-32-80 plate heat exchanger is recommended for use with heat pumps to separate the primary circuit from the heating system. If you are interested in a similar device, but for refrigerant, check out the refrigerant heat exchanger Nordic Tec Ba-68-40-F

- Maximum temperature range +230°C

- Flowrate - 12 m³/h

Heat Exchange Surface / Heat Transfer Area of a Ba-32-80 PHE - 2.560 m²

Most common use of the 80-plate heat exchanger

- central heating installations with coal boilers up to approx. 80 kW, eco-pea coal boilers up to approx. 80 - 90 kW - heat exchanger for large boilers of different fuel

- heat exchanger for separation of the heat pump from the central heating system, using a HP with a capacity of up to 16 - 18kW, up to 20 kW, split or monobloc - heat exchanger for a monoblock heat pump

- separation of gas and solid fuel boilers - in order to create a short circuit and balance pressures in the system (a function similar to a hydraulic separator)

- cooperation with glycol heaters, e.g. in heating workshops or production halls, warehouses, etc.

- refrigeration using thermal oil or similar media

- A variety of other applications in both heating and cooling, primarily industrial ones

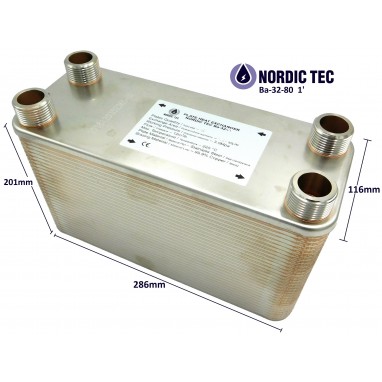

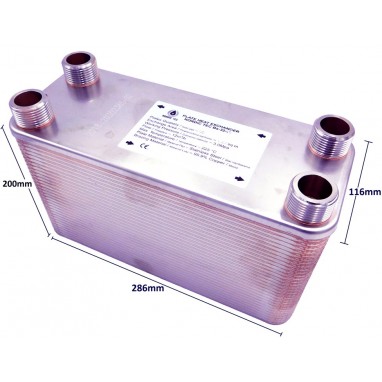

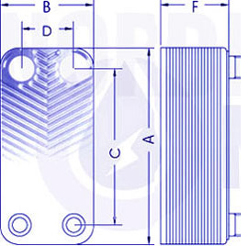

Dimensions:

(A) - 286 mm

(B) - 116 mm

(F) - 201 mm

(C) - 243 mm

(D) - 72 mm

In DOWNLOAD section you get the data sheet of the unit.

Heat exchanger for monoblock heat pumps - Ba-32-80 Nordic Tec

The above heat exchanger model is most commonly used for connecting heat pumps - ussually monobloc - to central heating systems. These are often monoblock heat pumps, although with the use of the heat exchanger , split-type pumps can also be separated.

The need to separate the heat pump from the heating system arises in various situations, especially when, for safety reasons, the decision is made to use glycol to protect the heating system from freezing . Some heat pump brands even require this, such as the well-known and popular manufacturer Rotenso, which is quite common in Poland.

Other situations may also arise where the use of a plate heat exchanger is necessary , such as the requirement to separate an old heating system from the heat pump's circuit for protection purposes (in this case, the heat pump should not operate in the same circuit, especially if it's an open circuit).

Selection of a Heat Exchanger for Heat Pumps | nordictec-store.com

Choosing a plate heat exchanger for a heat pump is not always straightforward or easy - but fortunately, it can be approached mathematically. The Ba-32-80 heat exchanger for heat pumps has a heat exchange surface of 2.56m², which should be taken as the key parameter for selection. The selection of a heat exchanger for a heat pump should follow the guideline that for every 10 kW of pump capacity, there should be around 1.5m² of heat exchanger plate surface - assuming the supply temperature in this system will be around 50°C.

However, selecting a plate heat exchanger for a heat pump in a low-temperature system is much more demanding. If the heat pump is intended to operate with temperatures as low as 30-35°C, which is typically the case in the newest constructions with underfloor heating, it's advisable to oversize the heat exchanger and have even 2.5-3m² of heat exchange surface per 10 kW of pump capacity .

These calculations include significant oversizing , aimed at enabling operation at very low temperature differentials ( minimizing the energy consumption of the heat pump). It's not to say that the heat exchanger won't serve the heat pump if these ratios are not met, but especially after a few heating seasons, the central heating system might not work optimally, particularly in terms of energy consumption .

It's worth noting that the above sizing calculation considers the use of antifreeze fluid (glycol) on the heat pump side. This significantly weakens heat transfer (since it's designed not to freeze, it naturally tends not to release heat). In the case of separating the heat pump in a water-based system, you can safely decrease these ratios by 10-15% without any consequences.

There have been cases where our specialists even matched the above model to heat pumps with capacities of 18-20 kW - but of course, this requires specific supply temperatures and knowledge. If you need consultation for selection, feel free to contact us.

We emphasize that this pertains to connecting the heat pump to the system, primarily for separation purposes ( often due to glycol use, and less commonly for other reasons like maintaining an open loop system in the building) . This heat exchanger is not recommended for refrigerants and coolants such as R-404, R-32, and similar.

Check another PHE unit from Nordic Tec if you're looking for a condenser for a HP. The unit below has a similar heat exchange area but it's designed for freon to water operation mode:

Plate Heat Exchanger for Heat Pumps Ba-32-80 - How Does It Work? | Nordic Tec

A plate heat exchanger is a quite popular heating device that transfers heat between 2 heating circuits . It enables the connection of two circuits, such as a fireplace, boiler, heat pump , or other types of heating, with the domestic heating system. It can also be essential when connecting a district heating system to a house or apartment . It's increasingly used to connect a heat pump circuit to a home.

In general , a plate heat exchanger consists of plates (nowadays mainly made of stainless steel, in this case there is 80 plates, wuite a large number ), which are brazed together in a rigid manner. Copper is often used as the brazing material, as in the case of the Nordic Tec Ba-32-80 model. This model has 80 plates, each with a surface area of 0.032m². The surface area of a single plate , multiplied by the number of plates, creates a total heat exchange surface area of 2.56m² - an impressive value considering the size of the device.

The heat exchange efficiency of plate heat exchangers is primarily determined by the heating exchange surface area.

Does the number of plates determine how efficient a heat exchanger is? | Ba-32-80 Nordic Tec

Yes, but not always. In the past, there wasn't a wide variety of heat exchangers on the market, and most of them, regardless of the manufacturer, were quite similar in size, parameters, and the size of individual plates. At that time, it was often simplified to compare just the number of plates. Logically, a 20-plate exchanger was considered weaker than a 30-plate exchanger, and it seemed obvious. Some installers from that era still hold onto strange, stereotypical "calculations" that suggest, for example, that 1 plate always corresponds to 1 kW of power, or that the selection of a heat exchanger should be based on 10 plates per 100 m² of building space (we occasionally encounter such notions when working on equipment selection). These are obvious fallacies, as the diversity of today's plate heat exchanger market and the wide range of models make the matter much more complex.

In reality, a heat exchanger with a larger number of plates will be more powerful than one with fewer plates, but only if the plates are of a similar size. The parameter we should focus on is the heat exchange surface area. For example, if a heat exchanger has 50 plates, but they are based on plates with a small surface area, say 0.012 m² each, then the total heat exchange surface area would be only 0.60 m². Compare this to a heat exchanger with 20 plates, where each plate has a surface area of 0.060 m², resulting in a total area of 1.20 m². In this case, the 20-plate heat exchanger could be twice as efficient as the 50-plate one. Therefore, checking the number of plates and relying mainly on this parameter for selection is a mistake; it should be just an additional factor. The main parameter that specialists consider when selecting is the heat exchanger's plate surface area.

__

You might be looking for a plate heat exchanger for your heat pump, but you might also want to better match the model and review more items from our catalog before making a decision.

Check out our category featuring the most commonly used heat exchangers for heat pumps / connecting glycol monoblok to the heating system.

NT Ba-32-80

1252 Items

New

No reviews

You might also like