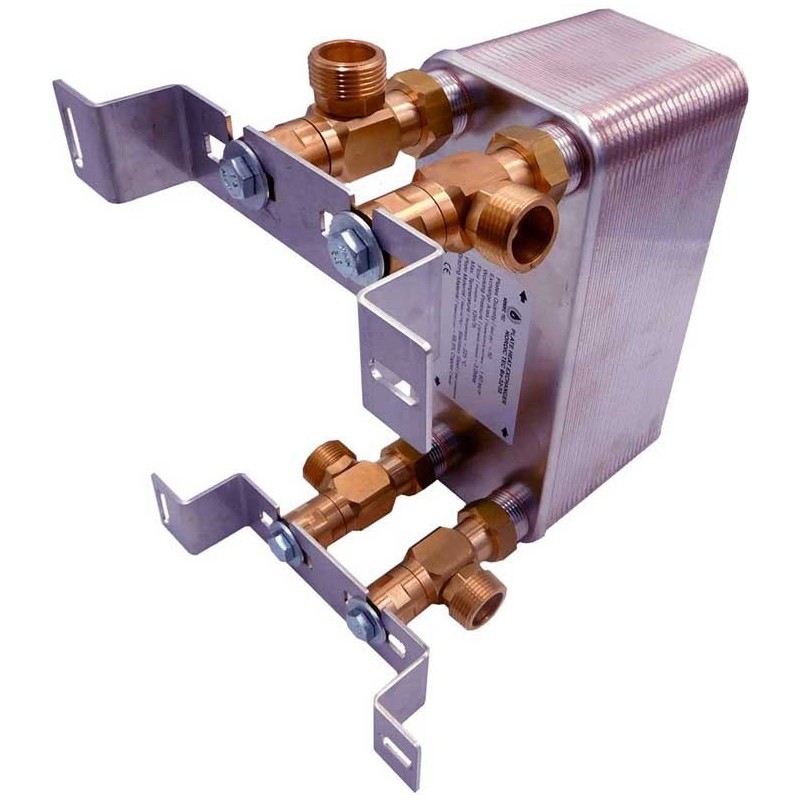

Plate Heat Exchanger NORDIC Ba-32-40 1" 230kW

Plate Heat Exchanger Heater for HVAC systems by Nordic Tec Ba-32-40

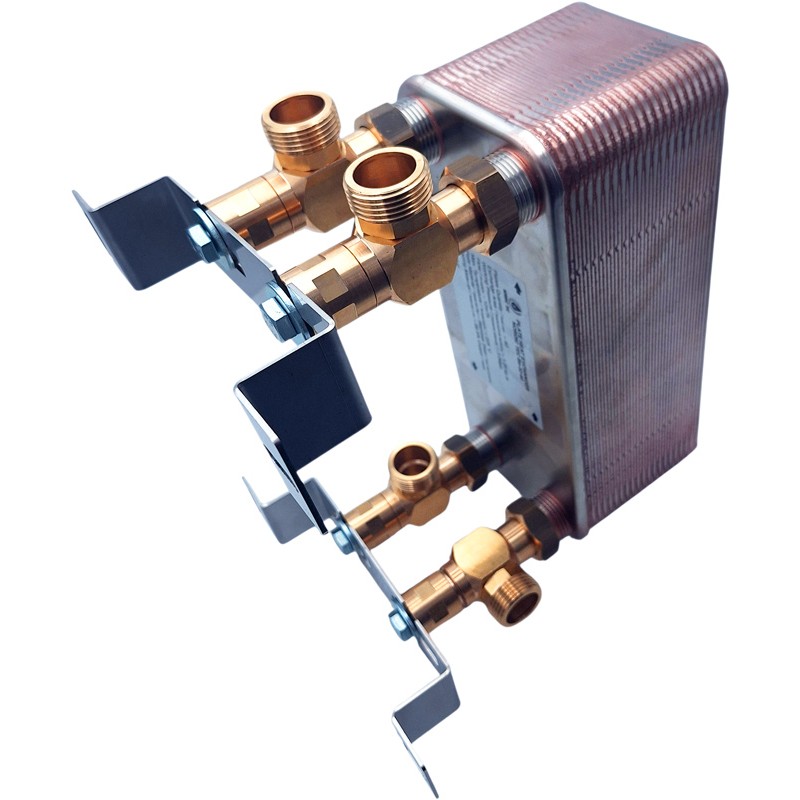

40-plate heat exchanger heater for central heating systems with 1-inch connections

- Plate Q'ty: 40 pcs.

- Connections: 1" BSP

- Heat Exchange Area: 1.280m²

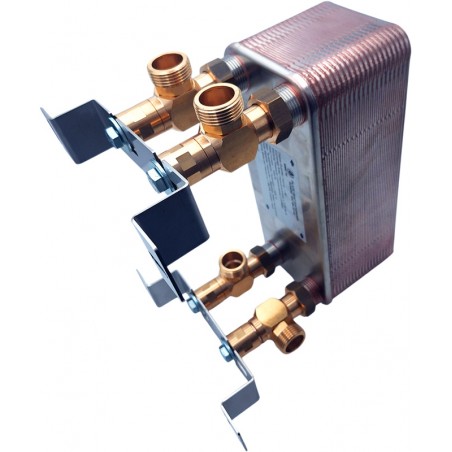

☑️ Optionally, the possibility to purchase a Ba-32-40 heat exchanger with insulation and a mounting kit (a holder with rotary fittings)

✅ Free delivery in: FR, IT, ES, DE, PL, AT, SI, DK, NL, BE, CZ, LV, EE, LT

Reference: NT Ba-32-40

Condition New

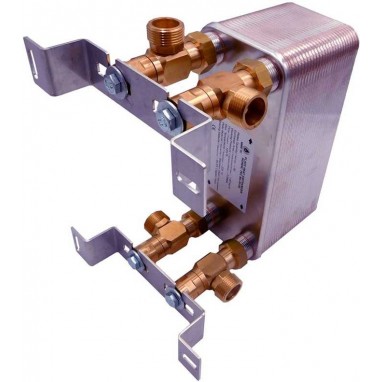

Heat Exchanger with 40 plates - Nordic Tec Ba-32-40 - 4x 1", 40 plates

40-plate heat exchanger with 1-inch connections

Technical details - Heat Exchanger with 40 plates - Nordic Tec Ba-32-40

- Stainless Steel S316L, brazed with 99,9% Cu

- Connections: 4x 1", BSP

- Working Pressure - <30 bar

- Test Pressure - 45-60 bar

- Max. temperature +230°C

- Flowrate - 12 m³/h

Heat Exchange Surface of the Heat Exchanger Ba-32-40 - 1.280 m²

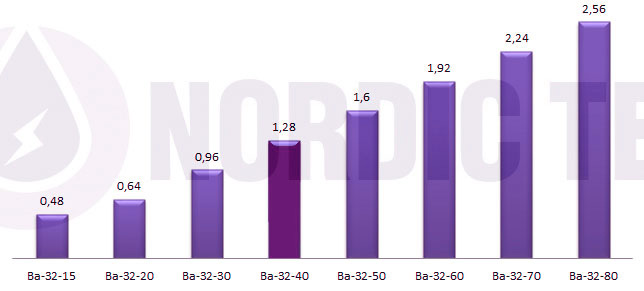

Plate Heat Exchanger Ba-32-40 1" compared with the serie Ba-32 (heat transfer area)

The 40-plate heat exchanger and its heat exchange surface area compared to other devices from the Ba-32 series, i.e., soldered plate heat exchangers of the same size. If you require a heat exchanger with a larger plate surface area than what the 40-plate model offers, we encourage you to check out larger models. The Ba-32 series offers heat exchangers with a surface area of up to nearly 3m² - as shown in the graph above.

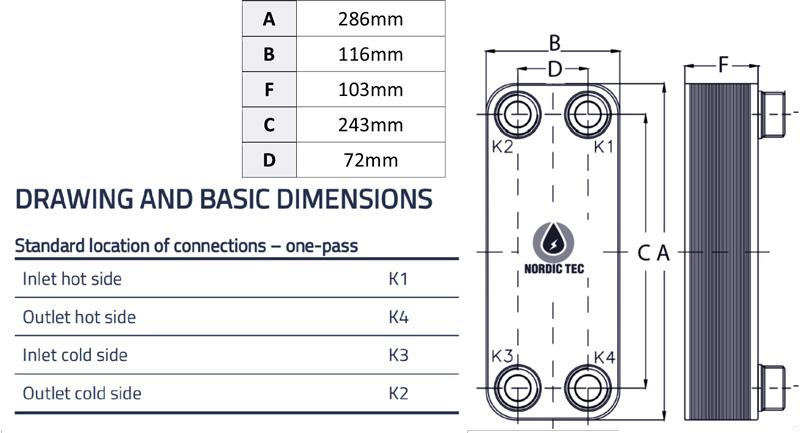

Dimensions - Heat Exchanger Ba-32-40

Frequent question from customers:

Can the Nordic Tec plate heat exchanger Ba-32-40 work with glycol or similar fluids?

Answer: Glycol or similar anti-freeze fluids are not considered aggressive media and do not require special heat exchangers made of special materials. Standard stainless steel heat exchangers by Nordic Tec are used for installations with glycol. However, attention should be paid to the thermal characteristics of glycol. It is a medium that does not freeze (which is why it is used in systems exposed to freezing), which also means that it does not transfer heat in the same way as water. Glycol weakens heat transfer, the more concentrated it is (glycol is usually mixed with water in proportions of 30/70 or 50/50), the more it hinders the operation of the heat exchanger. This must be taken into account when selecting the heat exchanger - which in practice means that a slightly larger device will be needed. Roughly speaking, in the case of using glycol on one side of the system, with a concentration of 50/50 with water, the heat exchange surface of the heat exchanger should be about 15% larger than in the case of a heat exchanger operating in a water-to-water system.

Can the Ba-32-40 plate heat exchanger work with heat pumps?

Yes, the Nordic Tec Ba-32-40 heat exchanger can work with heat pumps. In fact, it is designed to work with a variety of heat sources, including boilers, pellet stoves, biomass systems, and heat pumps. When connected to a heat pump, the Ba-32-40 can be used for home space heating and / or domestic hot water production. The size and capacity of the heat exchanger should be selected based on the heat pump's output (kW) and the heating demands of the building or system as a whole. Sizing a heat exchanger for a heat pump is a bit more sophisticated than for another heat sources, because there are different heating systems, operating on both very low temperatures and quite decent ones, so starting from cca 30°C till even 60°C.

The PHE Ba-32-40 is recommended for smaller HP systems with a heat pump of 4 - 9 kW, depending mainly on the temperature of operating. For bigger HP units - it's worth to consider the bigger heat exchangers from Ba-32 series, on the graph above we can check their heat transfer area in comparison to Ba-32-40.

More FAQ:

How much heat loss is there on a plate heat exchanger in a heating or hot water installation?

Although occasionally asked, the question of heat loss on a plate heat exchanger in a heating or hot water installation has no technical basis. With proper selection of the plate heat exchanger and correct connection of the device, the loss is almost zero and is below 1°C. The myth that the use of plate heat exchangers always results in a loss of, for example, 5 or 10°C is clearly nonsense. If we seriously consider this, we would come to the conclusion that the use of heat exchangers in this case would be economically unviable and the technology would not survive on the market. However, the use of this device in heating systems has developed very well over the years and there is increasing demand in the market. Heat loss on the heat exchanger can only occur when the system is cold (the medium then also returns cooled from the installation) and obviously needs to absorb more heat energy. After a few hours, this loss usually decreases and approaches zero. When the system is relatively warm, the loss stabilizes at a level close to zero.

How did the myth of heat exchanger's heat loss originate? When does heat loss occur in a plate heat exchanger?

As mentioned above, fouling in plate heat exchangers is usually caused by either incorrect equipment selection or installation errors. Below are some of the most common reasons:

- With a properly selected heat exchanger, the target loss should not occur, meaning it will be close to zero. Of course, proper selection of a heat exchanger means that it has the appropriate level of heat exchange surface area in relation to the power of the heating device (heat pump, fireplace or central heating boiler). If someone has experience with high heat exchanger losses, it is very possible that the device was simply undersized, which is the most common mistake made by laypeople - but unfortunately, also very often by installers. However, there may be other reasons as well.

- An abnormally high heat exchanger loss can also occur due to incorrect connection. Plate heat exchangers are most commonly connected in a so-called counterflow. If the hydraulic technician connects the exchanger with a disregard for the counterflow, we will deprive the exchanger of efficiency and then it will not function properly (this mistake happens quite often).

- Another mistake that can cause improper operation is the installation of the exchanger in a horizontal position, which will cause it to become airlocked. In this case, it will be clogged and it will be difficult to expect efficient heat exchange from it. Unfortunately, professionals do not always know this.

- Another cause of loss is incorrect adjustment of circulation pumps, especially on the hot side, or incorrect selection of pumps.

- A less common cause is the lack of installation of pre-filters before the heat exchanger. This can cause the exchanger to pull impurities from the system and block the flow after circulation pumps are activated. Filters before the exchanger are mandatory and must be installed before the first operation of the system.

___

or similar product cathegoty:

NT Ba-32-40

1159 Items

New

No reviews

You might also like

Remember you can always contact our service - if you don't know which HE is sufficient to your heat pump system

Remember you can always contact our service - if you don't know which HE is sufficient to your heat pump system